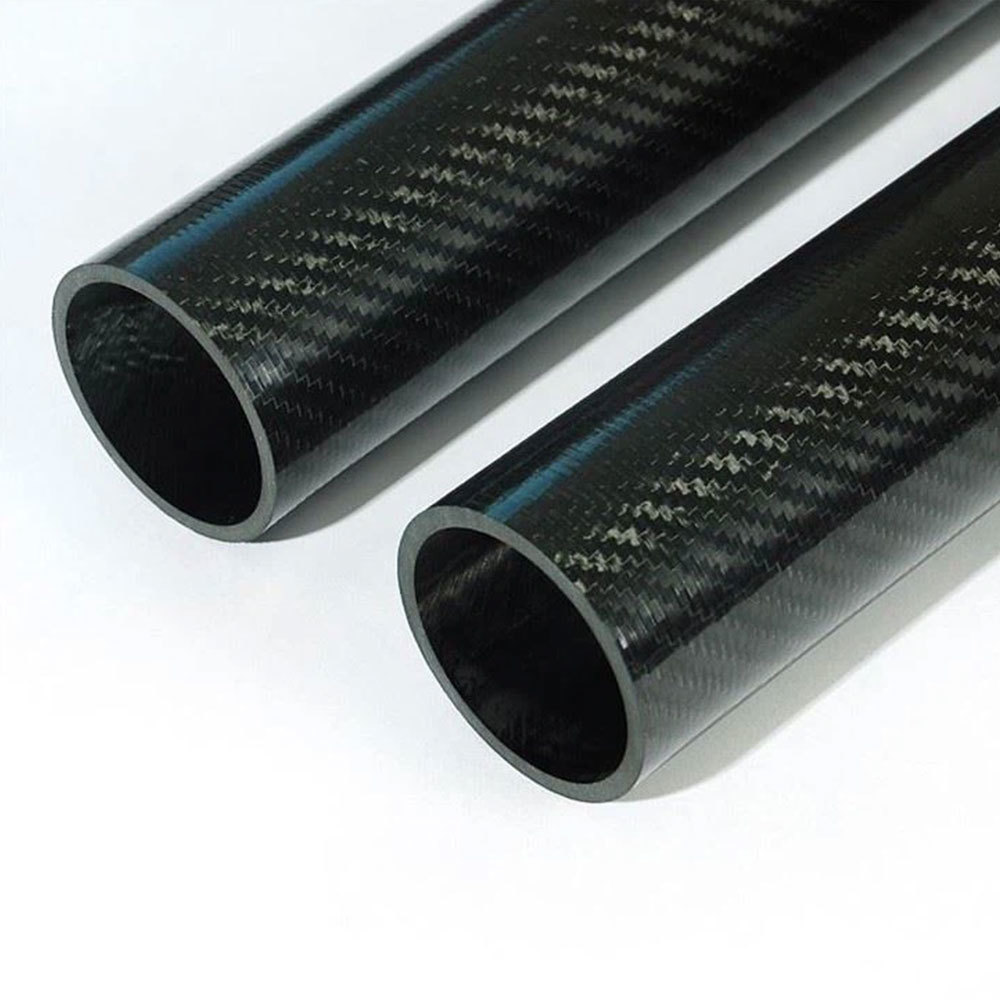

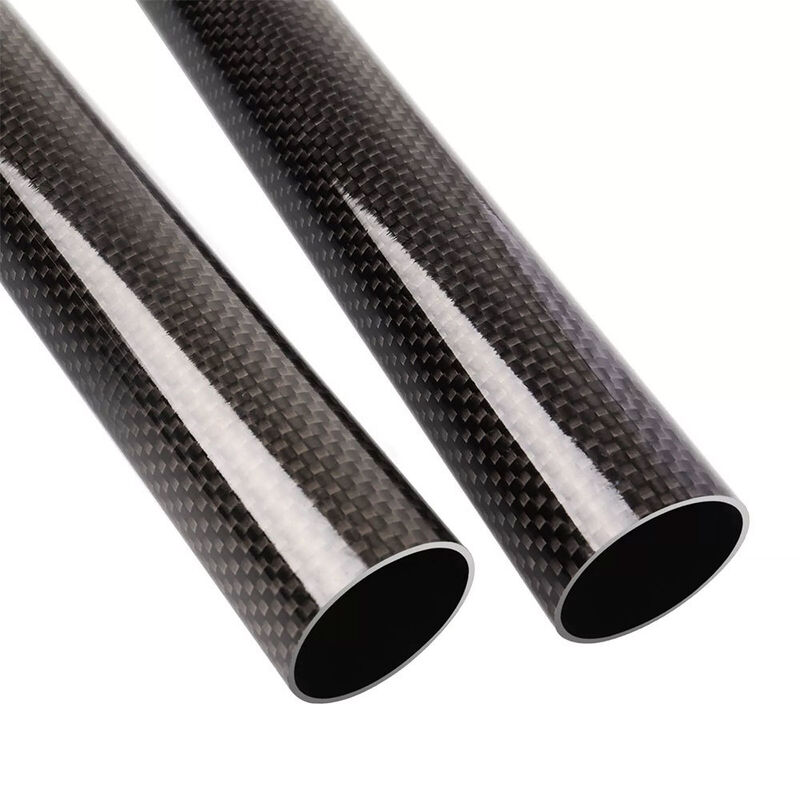

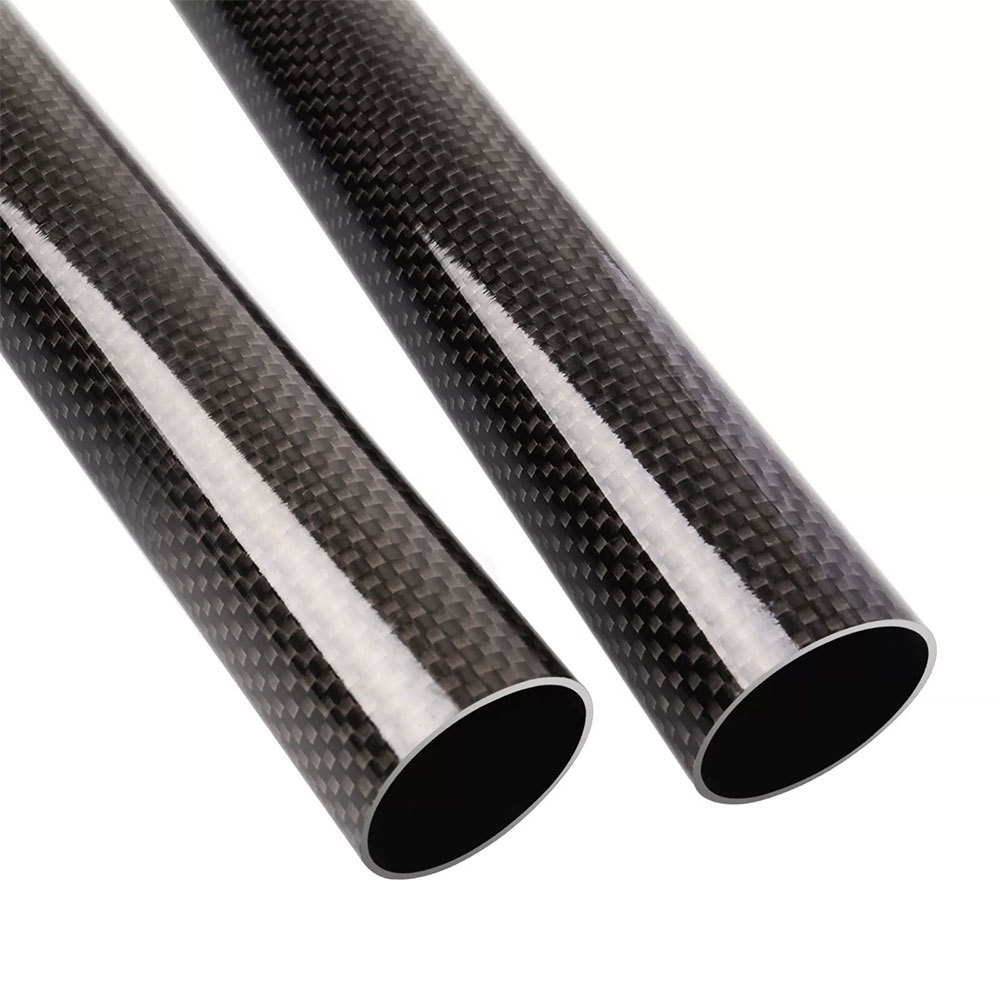

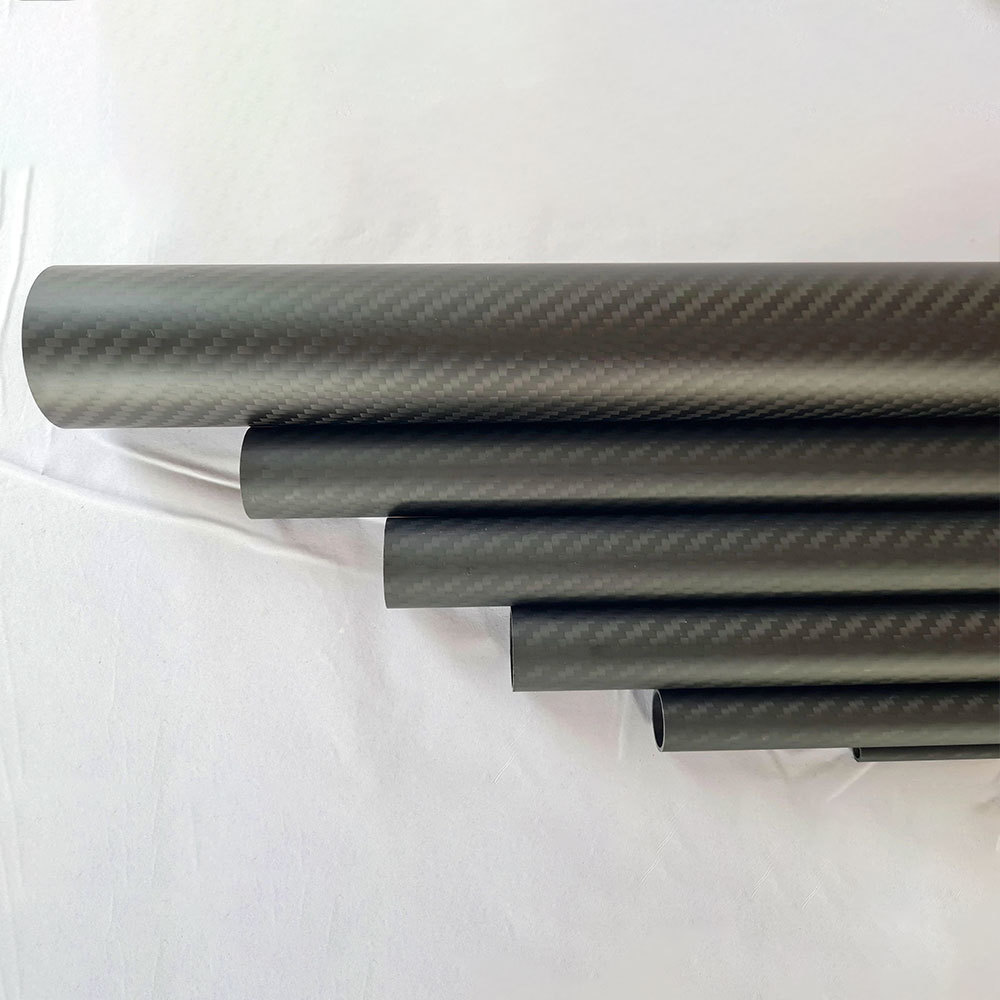

Custom 5mm OD X 3mm ID X 1000mm Length Roll Wrapped Carbon Fiber Tube 3K Glossy Pipe

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

Mr.

- Mr.

- Mrs.

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT