Product Description

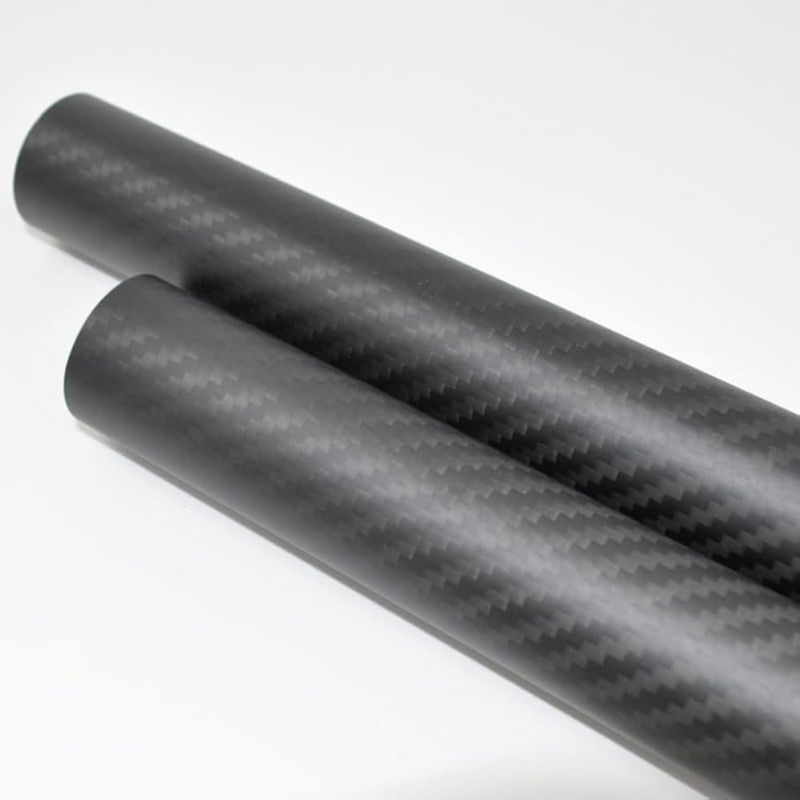

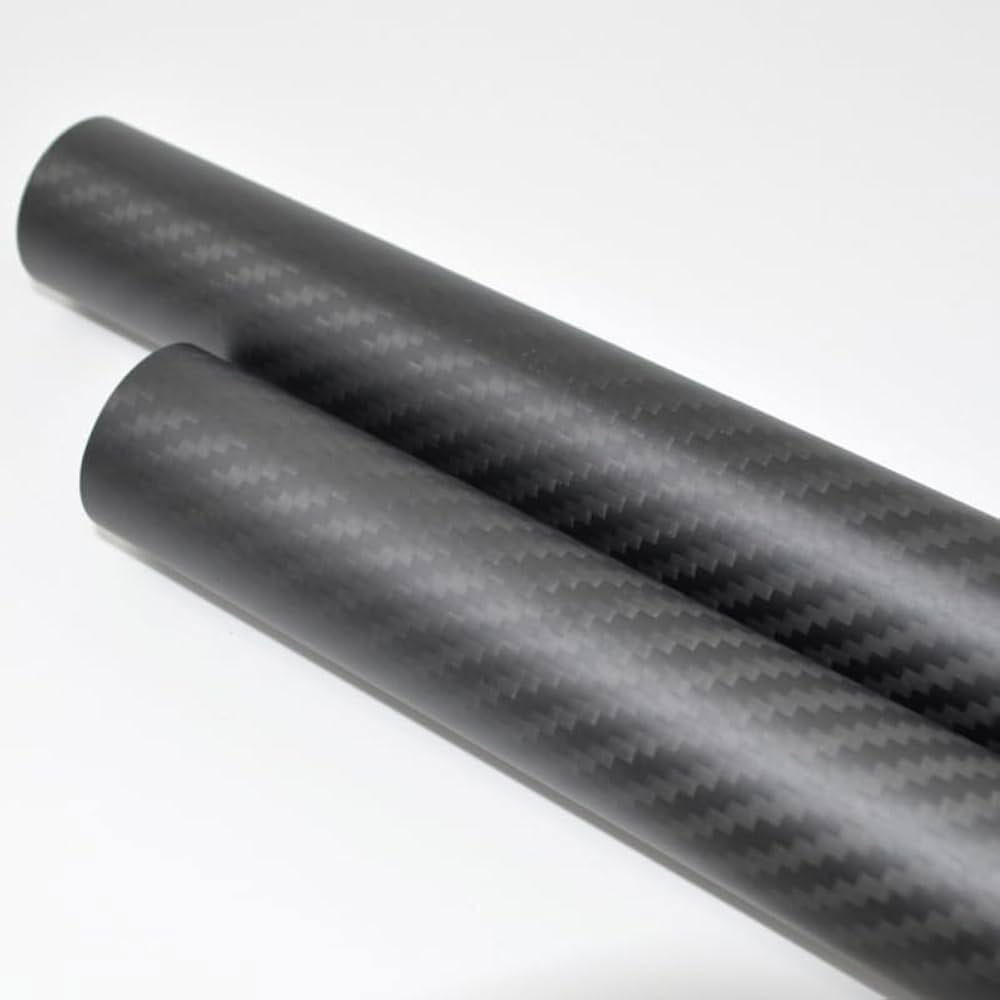

Precision Engineered 3K Matte Twill Carbon Fiber Hollow Round Tube

Description

The carbon fiber tube is made by the tube rolling process, and can be designed with multi-angle ply to create high-performance, high-quality carbon fiber tubes. It can be widely used in medical equipment, sports equipment, drones, industrial machinery, and various rollers.

All our light weight and high strength carbon fiber square tubing are made from premium quality unidirectional carbon fiber prepreg fabric and 3K twill/plain carbon fiber prepreg fabric.Fiberglass fabric is available.

Ultra-strength square carbon fiber composite pipes can be widely used as aircraft frames,truss ,agriculture drones or other special application.We can offer 1/4 ,3/4 or 1 inch square carbon fiber tube,or custom made shaped composites tubes based on different applications.

In general, the carbon fiber tubing is made from Toray T300 100% real carbon fiber prepreg fabric.Of course,we can also choose high modulus Toray T700 or T800 carbon fiber fabric to meet clients' special requirements.Additionally,Colored Kevlar or forged carbon fiber tubes also can be offered.

We produces round,square,rectangle,oval,elliptical,octagon,hexagonal and custom made carbon fiber tubes and profiles. Die cost can be returned based on order quantity.

Main Features

- High stiffness and strength

- Most Lightweight

- Low Density

- Safety

- Corrosion Resistance

- X-ray transparency

- Low CTE (Coefficient of Thermal Expansion)

- Chemical Resistivity

- Thermal and electrical conductivity

- Fatigue

- Durability

- Production Flexibility

Our Advantages

- 10+ years of experience

- Professional manufacturer

- Strict Quality Control

- Expert workers

- Close Tolerance

- Reasonable price

- Short Production Time

- Company Culture&Value

| Material |

Carbon Fiber Tube |

| Shape |

Round |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high-strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Properties and Benefits of Carbon Fiber Tubes

Strength-to-Weight Ratio

One of the most significant advantages of carbon fiber tubes is their exceptional strength-to-weight ratio. Carbon fiber tubes are known to be up to five times stronger than steel while weighing only one-fifth as much. This makes them ideal for applications where weight savings are crucial without compromising structural integrity. The specific strength (strength per unit density) of carbon fiber tubes can reach values around 1500 kNm/kg, significantly higher than that of traditional materials like aluminum and steel. This property is particularly beneficial in industries such as aerospace, automotive, and sporting goods, where reducing weight can lead to enhanced performance and fuel efficiency.

Moreover, carbon fiber tubes can be customized to achieve even higher specific strengths for advanced applications, such as in the construction of space structures or high-performance sports equipment. The ability to combine different fiber orientations within a single tube can enhance specific properties like torsional strength or impact resistance. For example, hybrid carbon fiber tubes, which incorporate other high-strength materials such as Kevlar, can achieve tensile strengths up to 4.0 GPa, making them suitable for extreme environments and high-stress applications. The density of carbon fiber tubes typically ranges from 1.5 to 1.6 g/cm³, contributing to their lightweight nature and ease of handling.

Corrosion Resistance

Carbon fiber tubes exhibit excellent resistance to corrosion, unlike metals such as steel and aluminum, which can degrade over time when exposed to moisture and chemicals. This corrosion resistance makes carbon fiber tubes ideal for use in harsh environments, including marine, industrial, and chemical processing applications. The inert nature of the carbon fibers and the stability of the epoxy resin matrix contribute to this resistance, ensuring long-term durability and reduced maintenance costs. Carbon fiber composites maintain their structural integrity and performance in environments where metals would fail, contributing to longer service life and lower lifecycle costs.

The high corrosion resistance of carbon fiber tubes also translates into significant cost savings over the lifecycle of a product. For instance, offshore oil and gas platforms use carbon fiber tubes for risers and other structural components to avoid the frequent and costly maintenance required for steel alternatives. The annual maintenance cost for steel risers can exceed $100,000, whereas carbon fiber risers require minimal upkeep, potentially reducing maintenance costs by up to 80%. Furthermore, the non-reactive nature of carbon fiber makes it an ideal choice for biomedical applications, where biocompatibility and resistance to body fluids are essential for long-term implants and prosthetics. Carbon fiber composites do not elicit immune responses, making them suitable for medical implants such as prosthetic limbs and spinal rods. The chemical inertness of carbon fiber, combined with its mechanical properties, ensures that it can be used in environments where other materials would fail or require extensive protective measures. Carbon fiber's biocompatibility reduces the risk of adverse reactions and extends the lifespan of medical devices and implants, often exceeding 20 years without degradation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!