Product Description

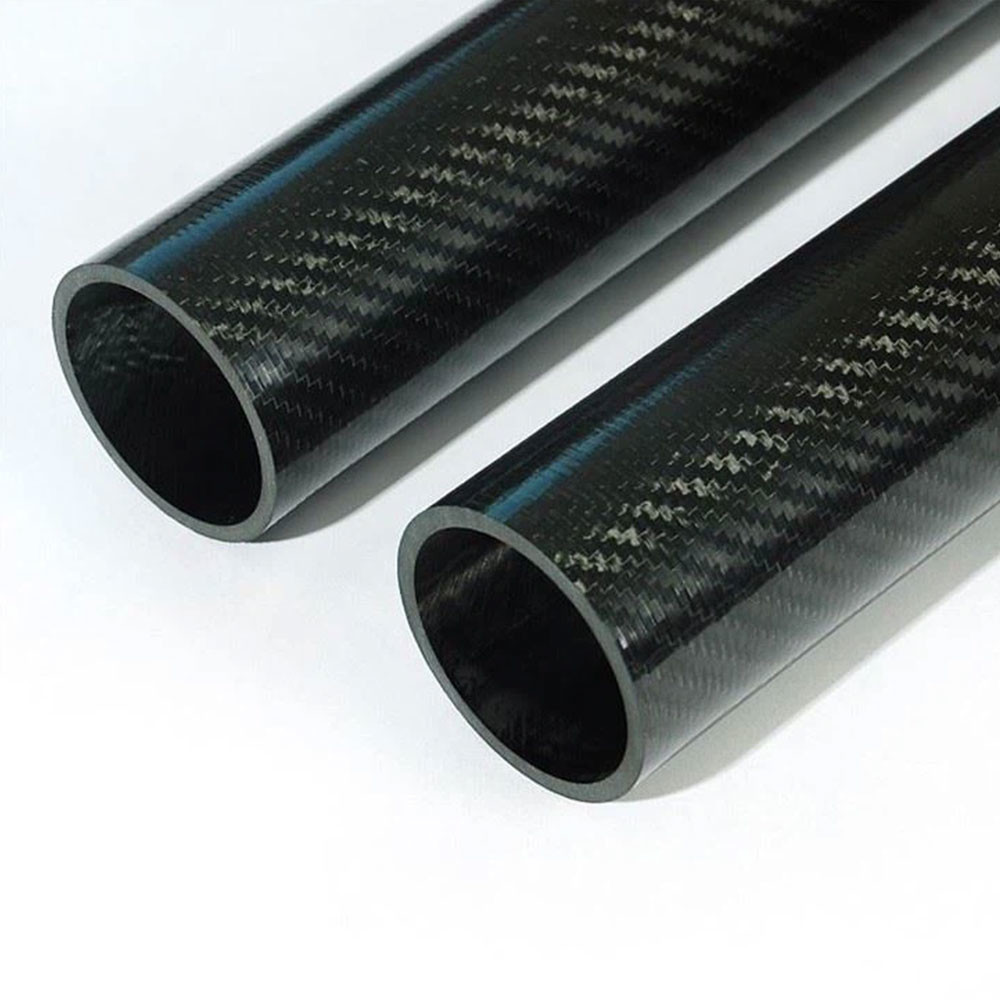

UV-Resistant Carbon Fiber 3K Matte Twill Tube 40X37mm, 1000mm Long - High Corrosion Resistance

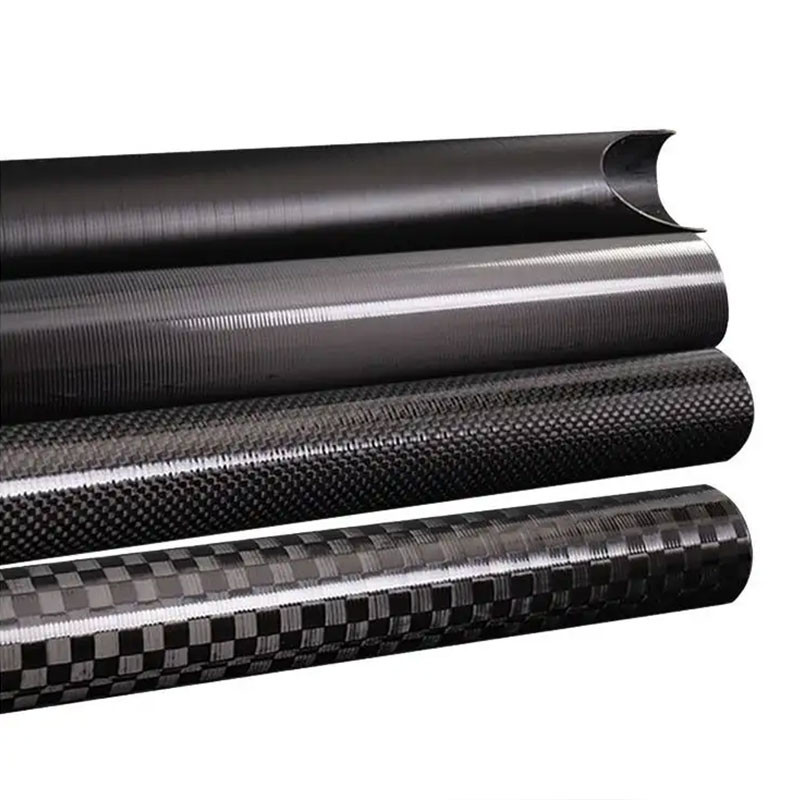

Our carbon tubes are also used in Light aviation and UAVs, the tubes are tested for Bending force. Those Roll-wrapped carbon fiber tubes are manufactured by wrapping multiple layers of 12k UD and 3k twill carbon fibre pre-pregs around a metal mold and then cured at high temperature. The UD pre-pregs are used in core layers whereas the twill is on the surface. Carbon Fiber 3k Roll wrapped high strength carbon fiber tubes matte twill tube finish.

Roll-wrapped carbon fiber tubes offer superior strength in general use to ‘pultruded' tubes (which have all their fibers running in the same direction.

The use of unidirectional fibers and maximum strength in the lateral axis does mean that the tube is not as strong across its diameter as it is along its length so should be used in such a way as to avoid unnecessary crushing forces across the tube.

Roll Wrapping

The phrase ‘roll wrapped' refers to the process used to manufacture these tubes. The prepreg carbon fiber is first laid up around a mandrel in multiple layers. Once the reinforcement is in place it is spiral-wrapped with heat-shrink tape before the whole assembly is oven-cured.

Features

- Made of Carbon Fiber material

- High Strength

- Stable dimension and UV-resistant

- High Corrosion Resistance

- Electrical & Thermal Non-Conductivity

Carbon fiber tubes are used in various industries due to their lightweight, durability, and high strength. In the aerospace industry, they are used in aircraft fuselages, wings, rotors, rockets, and spacecraft. Their lightweight improves fuel efficiency and performance. In the automotive industry, carbon fiber tubes are used in car chassis, sports car bodies, brake discs, and steering systems.

The combination of lightweight and high strength can enhance the performance of military equipment. Layers of carbon fiber tubes are produced in both 0° and 90° directions to achieve maximum strength, providing them with high strength in addition to the classic appearance of carbon fiber.

Carbon Fiber Tubes Technical Specifications and Applications:

Carbon fiber tubes are widely used in various industries due to their lightweight, durability, and high strength.

1- Aviation and Aerospace Industry: Used in aircraft fuselages, wings, rotors, rockets, and spacecraft. Their lightweight enhances fuel efficiency and performance.

2- Automotive Industry: Carbon fiber tubes are used in car chassis, sports car bodies, brake discs, and steering systems, aiding in weight reduction and performance enhancement.

3- Maritime Industry: Utilized in marine vessels, sailboats, mast poles, and underwater vehicles due to their resistance to seawater and lightweight nature.

4- Sports Equipment: Found in bicycle frames, golf clubs, fishing rods, tennis rackets, and kayak paddles, providing athletes with lightweight and durable equipment.

5- Construction Materials: Used in construction and building industries, particularly in applications like concrete reinforcement and strengthening.

6- Military Applications: Employed in military equipment such as armor plates, helicopter rotors, aircraft components, and weapon systems due to their lightweight and high durability, enhancing performance.

| Material |

Carbon Fiber Tube |

| Shape |

Round/oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!