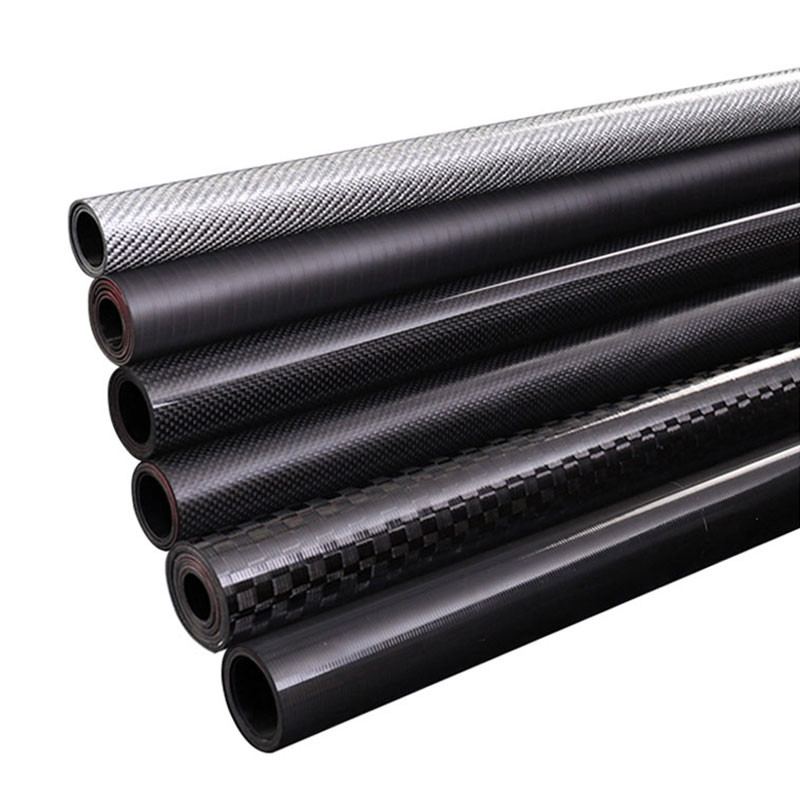

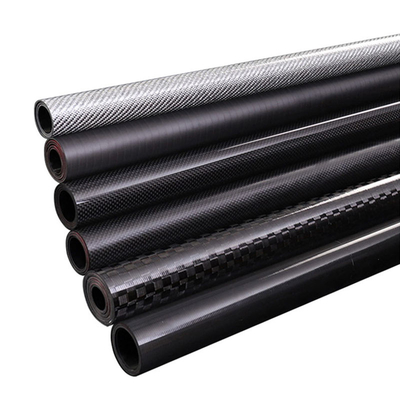

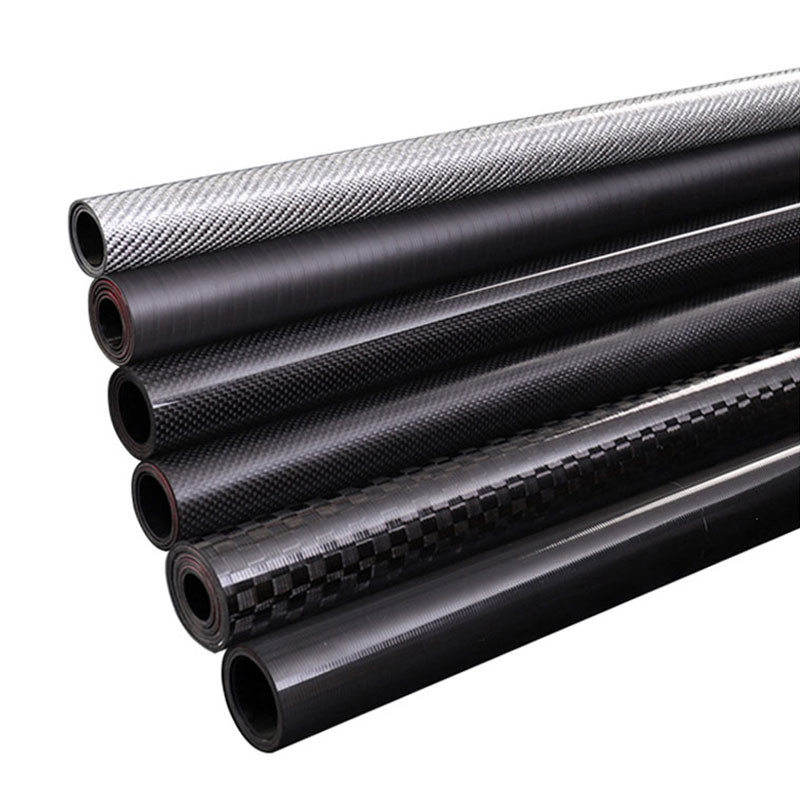

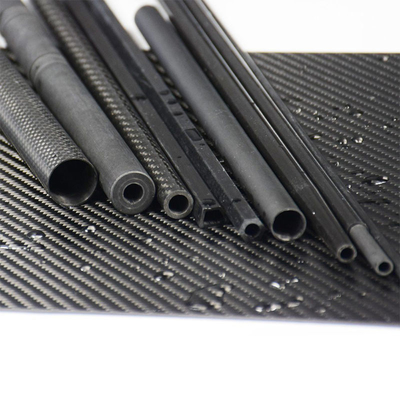

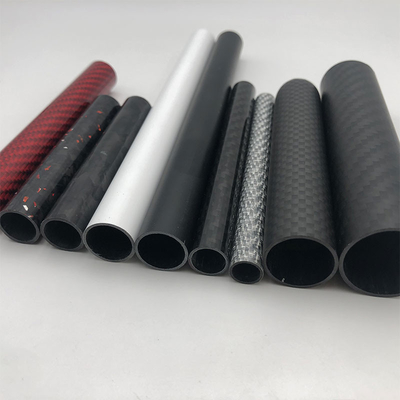

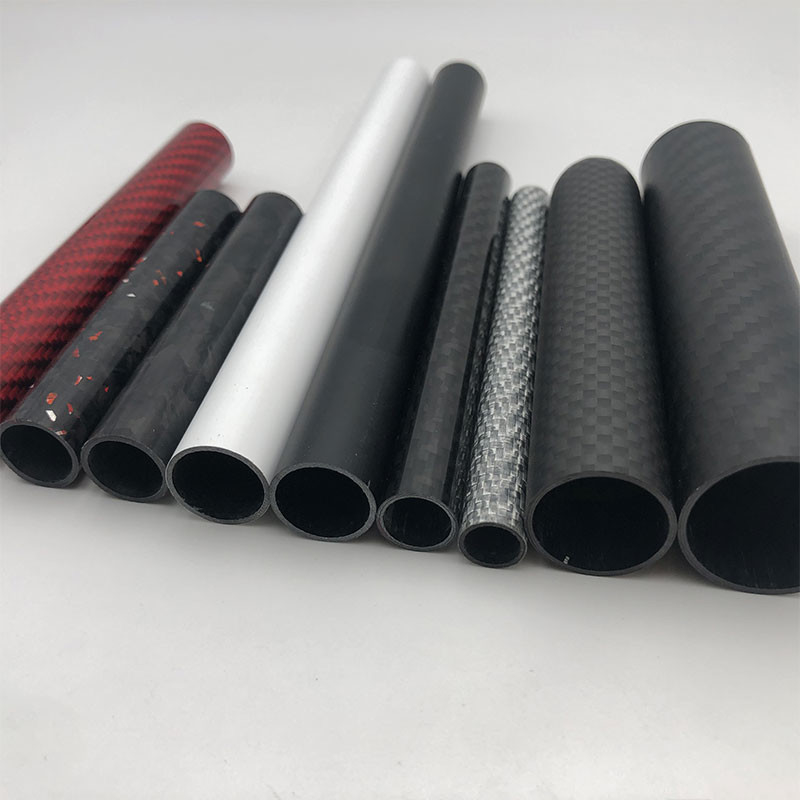

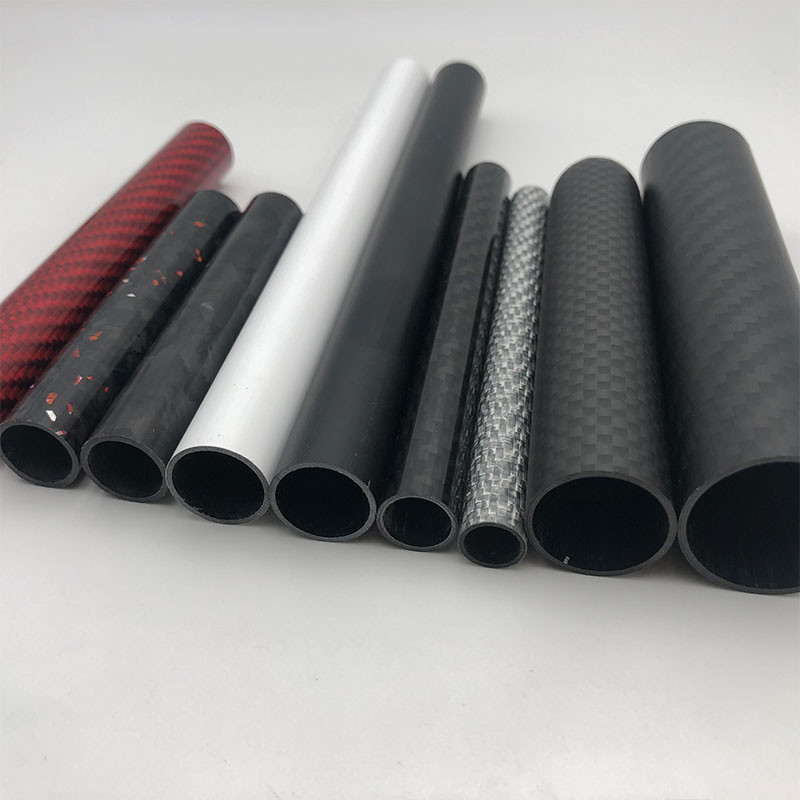

High Precision 24*22*1000mm Carbon Fiber Tube - High-Performance & Lightweight

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

Mr.

- Mr.

- Mrs.

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT