Product Description

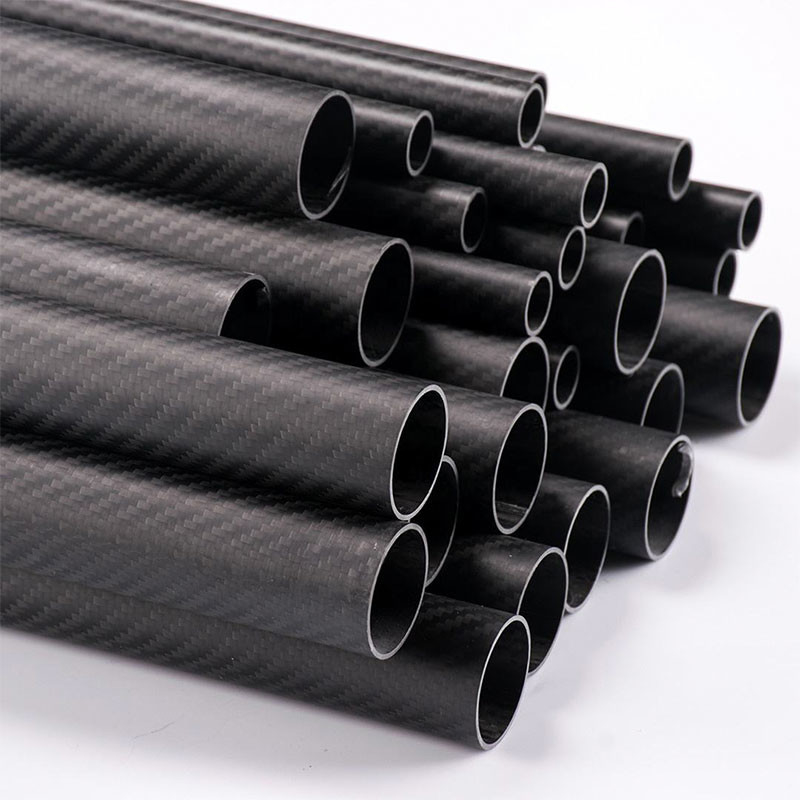

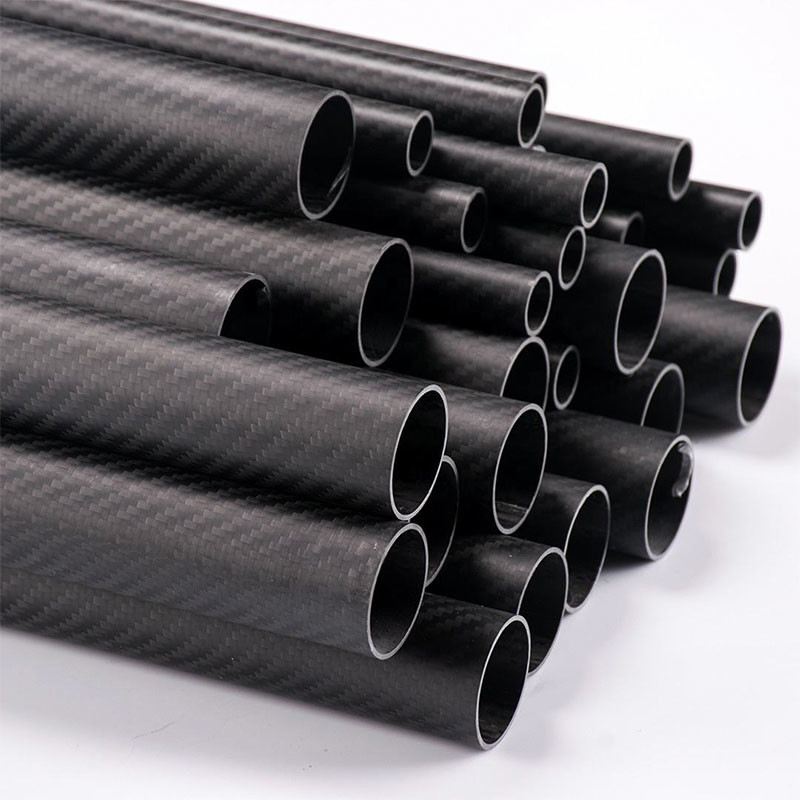

High Strength Roll Wrapped Twill Woven Finish Round 3K Carbon Fibre Tube

A 3K carbon fiber tube is a type of tubing that is made from carbon fibers that are interwoven in a specific pattern, known as a 3K weave. The term 3K refers to the number of fibers in one bundle, which is approximately 3000. The result is a tube that is extremely lightweight, strong, and durable.

Carbon fiber tubes have a range of applications, including in the aerospace industry, sports equipment, and automotive parts. They are ideal for applications that require high strength and stiffness, while also being lightweight.

3K carbon fiber tubes are commonly used as structural supports, such as in drone frames, bicycle frames, and even in certain musical instruments. They are also used in the construction of robotic arms, high-performance kites, and as reinforcement for concrete structures.

Overall, 3K carbon fiber tubes are an excellent choice for applications where strength, stiffness, and lightweight design are essential.

Carbon fiber tube offers exceptional performance characteristics which makes it a popular material of choice, particularly in high-performance applications. Here are some of the main performance characteristics of carbon fiber tubes:

High Strength-to-Weight Ratio: Carbon fiber tubes have excellent strength-to-weight ratio, making them significantly stronger than aluminum and steel while being much lighter in weight. This property makes carbon fiber tubes ideal for applications that require superior strength and stiffness in lightweight designs.

Stiffness: Carbon fiber tube exhibits higher stiffness compared to traditional materials such as steel or aluminum. This increased stiffness allows for better control over vibrations and higher accuracy in structural applications.

Durability: Carbon fiber tubes are extremely durable and resistant to fatigue under cyclic loading. They can also withstand exposure to harsh environments, making them ideal for structural applications in extreme climates or corrosive environments.

Anti-Corrosion Properties: Carbon fiber tubes have excellent anti-corrosion properties, which makes them less susceptible to rust and other forms of corrosion. This property makes them ideal for use in marine and offshore applications.

In summary, carbon fiber tubes offer an impressive combination of strength, stiffness, durability, and anti-corrosion properties. These performance characteristics make them ideal for a range of high-performance applications across multiple industries.

Application of Carbon Fiber Tube

- Automobiles parts

- Bicycle parts

- Aerospace and navigation

- Propellers parts

- Sports equipment: golf, ski pole, hockey pole, climbing pole etc.

- Copters and toys

- Kite frame

- Camera parts

- Hunting bow and arrows

- Tools handles

- Sailing mast

- Luggage parts

- RC cars parts

- Construction and Bridge reinforcement and strengthening

- ECT.

| Name |

3K Twill Carbon Fiber Tube |

| Feature |

1. Made of high modulus 100% carbon fiber imported from Japan with epoxy resin |

| 2. Great replacement for the low-grade aluminum wing tubes |

| 3. Weights only 1/5 of steel and 5 times stronger than steel |

| 4. Low Coefficiency Of Thermal Expansion, High-Temperature Resistance |

| 5. Good Tenacity, Good Toughness, Low Coefficiency Of Thermal Expansion |

| Specification |

Pattern |

Twill, Plain |

| Surface |

Glossy, Matte |

| Line |

3K Or 1K,1.5K, 6K |

| Color |

Black, Gold, Silver, Red, Bue, Gree(Or With Color Silk) |

| Material |

Carbon Fiber Fabric+Resin |

| Carbon Content |

68% |

| Size |

Type |

ID |

Wall thickness |

Length |

| Round Tube |

6-60 mm |

0.5,0.75,1/1.5,2,3,4 mm |

1000,1200,1500 mm |

| Square Tube |

8-38 mm |

2,3 mm |

500,600,780 mm |

| Application |

1. Aerospace, Helicopters Model Drone, UAV, FPV, RC Model Parts |

| 2. Manufacture Fixtures And Tooling, Industrial Automation |

| 3. Sports Equipment, Musical Instruments, Medical Device |

| 4. Building Construction Repair And Strengthening |

| 5. Car Interior Decoration Parts, Art Products |

| 6. Others |

| Packing |

3 layers of protective packaging: plastic film, bubble wrap, carton |

| (Normal size: 0.1 * 0.1 * 1 meter(width*height*length) |

The service we can supply:

| Our Processing |

CNC machining, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding and so on |

| Finish |

Sandblast, polish, color anodize, zinc-plated, nickel-plated. power coating and so on |

| Tolerance |

0.008-0.01mm |

| Inspection |

100% inspection before shipping |

| Package |

Standard suitable package / Pallet or container / As per customized specifications |

| Payment Terms |

30 -50%T/T in advance, the balance before delivery; PayPal or Western Union is acceptable |

| Shipment Terms |

1) 0-100kg: express & air freight priority,

2) >100kg: sea freight priority,

3) As per customized specifications |

| Trade terms |

FOB, CIF, CFR |

| Drawing format |

JPEG, PDF, DWG, DXF, IGS, STEP.CAD |

| Note |

The products shown here are only to present the scope of our business activities. We can manufacture custom parts according to your drawings or samples. |

Welcome to wholesale our high-performance reinforcement carbon fiber tube with 3k twill or plain-woven patterns of glossy or matte surface. As one of the leading China manufacturers and suppliers, we will offer you the best quality products and excellent service. For more info, contact our factory now.

Frequently Asked Questions About Carbon Fiber Tubes

1. What’s the feature of your product?

There are many good characteristics of our carbon fiber product, such as lightweight, high strength, durable, and fashion, etc.

2. Can I have a sample order?

Yes, we welcome sample orders to test and check quality. Mixed samples are acceptable. For some products, we can offer free samples. Clients just need to bear the shipping cost.

3. What is the lead time?

The sample needs 1-3 days, mass production depends on order quantity. Normally 6-9 days.

4. Can you accept the mixed batch of different products?

Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc.

5. What file need if need to do CNC Cutting or molding products?

We Need CAD DXF or DWG files for CNC cutting, 3D, STEP, STP, IGS Files for molding.

6. How do we do quality control?

We have inspectors to check each procedure to avoid any mistakes.

7. How do you pack the goods?

We wrap the goods with soft plastic bags first and then pack them using a cardboard box with foam board inside.

8. How is your after-sale service?

We provide our clients with excellent after-sale service including logistics tracking, application guide, problem solution,

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!