Product Description

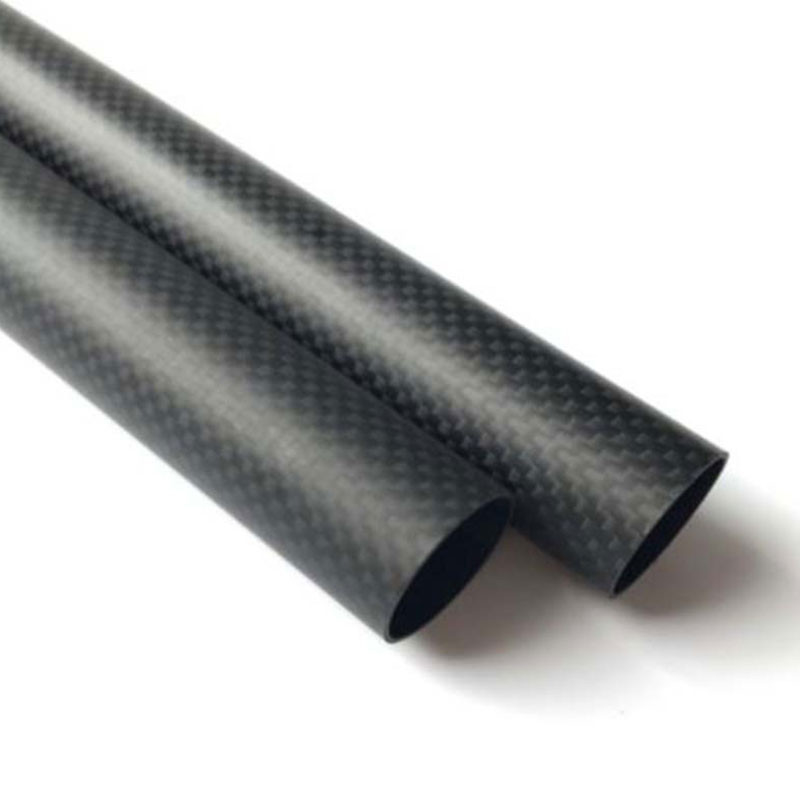

High Pressure Resistance 100% 3K Carbon Fibre Tube 10x8x1000mm

What are carbon fiber tubes used for?

Carbon fiber tubes are used in numerous applications like tactical ladders, trusses, beams, and more. Carbon fiber is typically chosen over traditional materials such as aluminum, steel, and titanium because of the following properties: High strength and stiffness to weight. Excellent resistance to fatigue.

How strong is carbon fibre tube?

Carbon fiber is very strong, very stiff, and relatively light. The stiffness of a material is measured by its modulus of elasticity. The modulus of carbon fiber is typically 34 MSI (234 Gpa). The ultimate tensile strength of Carbon Fiber is typically 600-700 KSI (4-4.8 Gpa).

Is carbon fiber stronger than steel?

Though steel is generally considered the standard when it comes to construction and industrial settings, in terms of strength to weight ratios, carbon fiber is actually significantly stronger than steel. In this application, “strength” is defined by a material's resistance to deformation or “modulus of elasticity”.

Why is carbon fiber better than plastic?

Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. Carbon fiber is used on car modifications to give you a stylish, strong, and lightweight addition to your vehicle.

Carbon Tubes made with Roll Wrap Technology

A large percentage of our composite tubes are engineered utilising what’s known as a ‘male moulding process’ often referred to as “roll wrap”. As a carbon tube supplier with over 40 years of composites experience, we have found this method for construction to be the optimal technique for manufacturing thin-walled composite tubing.

This process has been refined and developed over decades of manufacturing high-quality industrial components for the aerospace, defence, motorsport, marine and industrial components sectors all over the world. Roll-wrapped carbon fibre tubes offer optimal performance for a wide range of applications.

| Material |

Carbon Fibre Tube 10x8x1000mm |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Carbon Fiber Customized Pultruded Profiles

The Carbon Fiber pultruded profiles are available in varying sizes and shapes. LIJIN Composites is capable of supplying customized carbon fiber products in line with customers’ specific requirements. With the right product design, development team, and in-house manufacturing facility, we can easily cater to carbon fiber pultruded profiles to meet the most demanding industry specifications. Our pultruded components are easy to work with. They can be cut with a band saw, coping saw, scroll saw, end mill, or Dremel tool.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!