Product Description

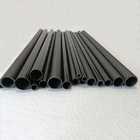

OD 100mm X ID 96mm X 1000MM 100% Roll Wrapped Carbon Fiber Tube

Carbon fiber tube with mesh view made entirely with high-quality carbon fiber. It is real carbon fiber, pressed and cured in the oven. With constant thickness, very high hardness, and very little weight. If what you are looking for are the benefits of the carbon tube with mesh aesthetics, this is your product.

If you need a tube with other lengths, diameters, or thicknesses, do not hesitate to contact us, we can manufacture it.

Features:

- Lightweight and high strength

- High Corrosion Resistance

- Superior Dimensional Stability

- Non-Magnetic Electromagnetic

- Excellent Structural Properties

- Environmentally Safe

Application:

- Automotive

- Sporting Goods

- Light Aircraft Tubing

- Advertising Panels

- Construction

- Robotic Arms & Supports

- Advertising Panels

- Power Generation

- Corrosion Resistant Equipment Marine

- Mechanical Equipment

- Photography & Sound Booms

- Wastewater Treatment

| Product Name |

100MM Carbon Fibre Tube |

| Material |

100% Carbon Fiber |

| Color |

Black or custom |

| Surface |

Matt/Glossy |

| Size |

Custom thickness and length |

| Fiber Specifications |

1K/3K/12K |

| Weaving Style |

Plain/Twill |

| Fiber Type |

1. Carbon fiber+carbon fiber

2. Carbon fiber+ glass fiber

3. Carbon fiber+aramid fiber |

| Application |

1. Aerospace, RC model parts Helicopters Model

2. Manufacture fixtures and tooling

3. Industrial automation and robotics

4. Sports equipment

5. Musical instruments

6. Scientific apparatus

7. Medical device

8. Others |

| Our Product |

Carbon fiber tube, carbon fiber plate, carbon fiber profiles. |

WHY COMPOSITES?

The majority of our clients move from the use of metal to composites to help them achieve a specific need.

1. To help them reduce the weight of a particular component

The ‘specific strength’ of an object is defined as the strength of the material it is constructed from, divided by its weight. In this calculation, by substituting a composite for a metal the weight of the material reduces significantly. In turn, this means that the composites’ strength-to-weight ratio is vastly higher than metal alternatives. This unique benefit has enabled our clients to replace many aluminum and metal parts with composite alternatives.

2. To reduce corrosion on an item

While metal is a very durable and hardwearing material, it isn’t impervious to the effects of the elements – air, water, ice, sand, and other elements can all contribute to corrosion in metal components – reducing their effectiveness and lifespan over time. In environments labeled as ‘normal’ and ‘aggressive’, composites have been proven to offer a much higher level of resistance to this naturally occurring corrosion – increasing the lifespan of components. This improved level of resistance is what makes composite such an attractive material for marine and aerospace applications.

3. Increased resistance to repetitive strain

Over time – all materials are subject to strain and deformation. Where metals and materials like aluminum can end up becoming permanently stretched or distorted, Composites are able be designed to experience extensive deformation without taking a permanent set. This ability to deal with repetitive strain over prolonged periods of time has seen the materials extensively used in the manufacture of aerospace wings and other components.

4. Low CTE (coefficient of thermal expansion)

When materials are subjected to heat, the fibers within them expand increasing the size of a component and potentially its effectiveness. The coefficient of thermal expansion refers to the rate at which the size of the material changes in relation to this temperature change. When working with composites, this CTE is significantly less than seen in metals, with carbon being the most effective material with a CTE close to zero. The replacement of materials like INVAR (an Iron / Nickel alloy) with composites is a good example of how our products have been deployed in the field of metrology.

5. X-ray Transparency

As a material, Carbon fiber is actually transparent to x-rays making it a material of interest to many sectors but most notably the medical sector.

Talk to our team of composites experts today to discuss your requirements with us in detail!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!