Product Description

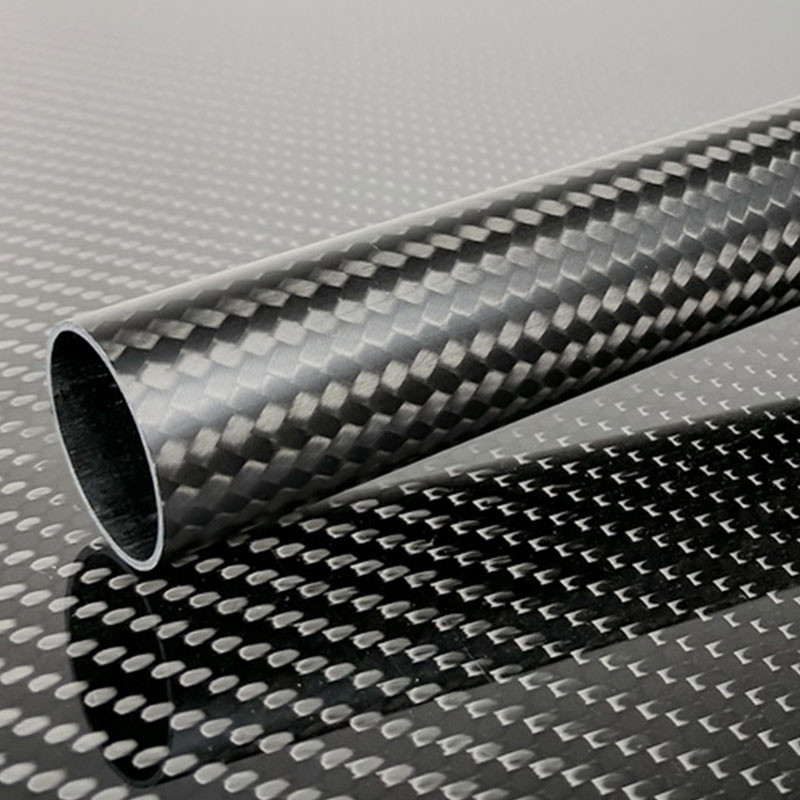

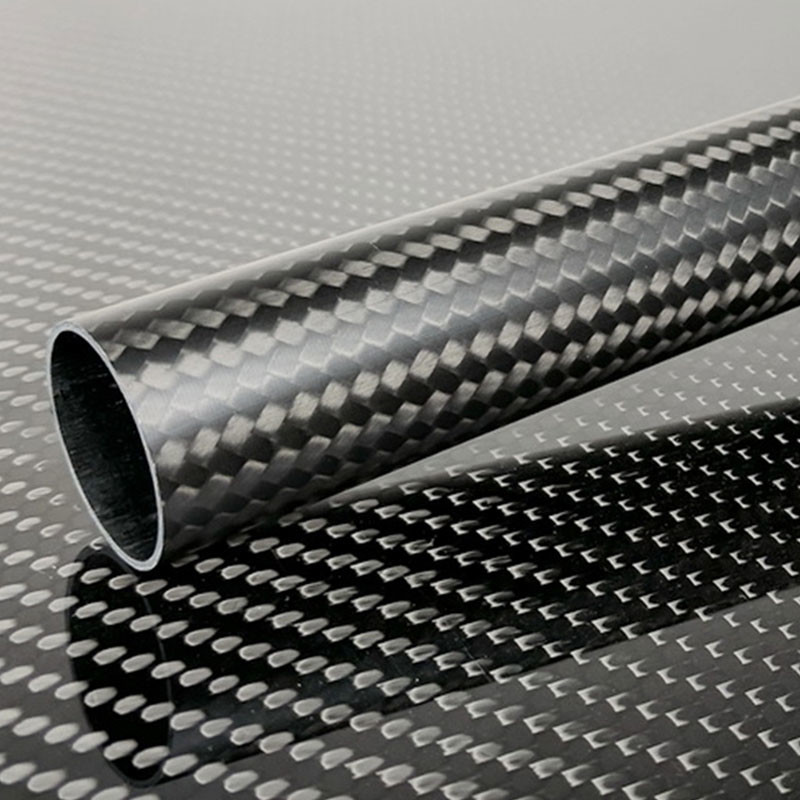

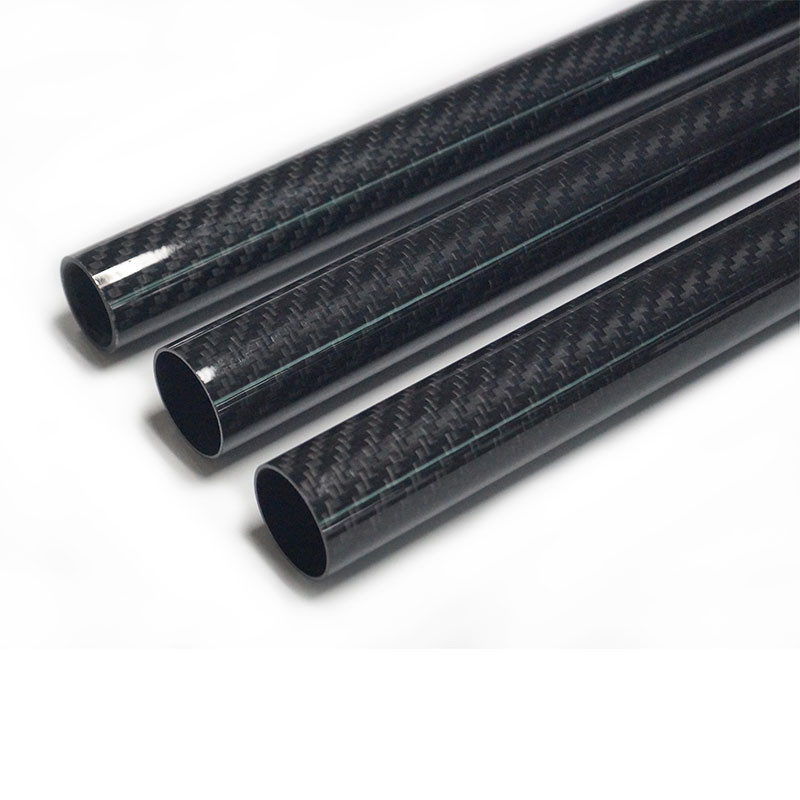

Good Durability 100% 3K Woven Finish Roll Wrapped Carbon Fibre Tube

The tube is made from woven fabric so there are fibers running both along the tube and circumferentially. The surface finish is gloss and exposes the plain weaves pattern.

Unique Benefits of Composites and Carbon Fibre Tubes

1. True zero degrees axial fibre alignment

A result that is not achievable by utilizing alternative ‘winding technologies’, your finished carbon tube will benefit from fibres that are perfectly aligned precisely where they should be; ensuring the perfect carbon fibre tube for your application – EVERY TIME!

2. Localised Reinforcements

In addition to creating tubes from Composites, our engineers are able to introduce additional materials anywhere along the tube to reinforce a particular section in line with your exact requirements.

3. Tapered Carbon tubes

When working with pultrusion manufacturing processes it is generally not possible to deliver an end product with a tapered tube. By employing our Roll Wrap technique, we are able to deliver a perfectly tapered tube – experience gained during decades of experience creating high-performance fishing rods.

4. Choice of Finishes Available

Our composite tube specialists are able to deliver a range of surface finishes on your end product – ranging from smooth-to-the-touch matte finish options, a painted tube of a particular colour, or just a ‘classic’ woven carbon fibre finish. No matter your requirements, we are able to provide you with the perfect end product for your customers’ needs.

5. Repeatable quality: The Very Best, Every Time

With our focus on the highest possible standards and with the tightest possible tooling tolerances we are able to offer you a consistent level of quality; delivering the highest quality composite tubes, every time.

6. Affordable Tooling

Due to the way, we manufacture our composite tubes, setup for jobs does not require the expensive tooling and mold setup costs associated with traditional molding methods. Even in the unlikely situation where we don’t have the correct size tool for your composite tube off the shelf, the manufacture of these new tools and casts is cost-efficient and affordable for businesses of all sizes.

| Material |

Woven Carbon Fibre Tube |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

WHY COMPOSITES?

The ‘specific strength’ of an object is defined as the strength of the material it is constructed from, divided by its weight. In this calculation, by substituting a composite for a metal the weight of the material reduces significantly. In turn, this means that the composites’ strength-to-weight ratio is vastly higher than metal alternatives. This unique benefit has enabled our clients to replace many aluminum and metal parts with composite alternatives.

Over time – all materials are subject to strain and deformation. Where metals and materials like aluminum can end up becoming permanently stretched or distorted, Composites are able to be designed to experience extensive deformation without taking a permanent set. This ability to deal with repetitive strain over prolonged periods of time has seen the materials extensively used in the manufacture of aerospace wings and other components.

Our Service:

1. It ensures that a year of quality assurance and 24 hours online customer service.

2. Protection of your sales area, ideas of design, and all your private information.

3. Request for samples is accepted.

4. Drilling and slotting are accepted.

5. We guarantee the products to be manufactured with the finest materials and mature technics.

All tubes can be repaired at no charge if returned to us, postage prepaid, within one year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!