Product Description

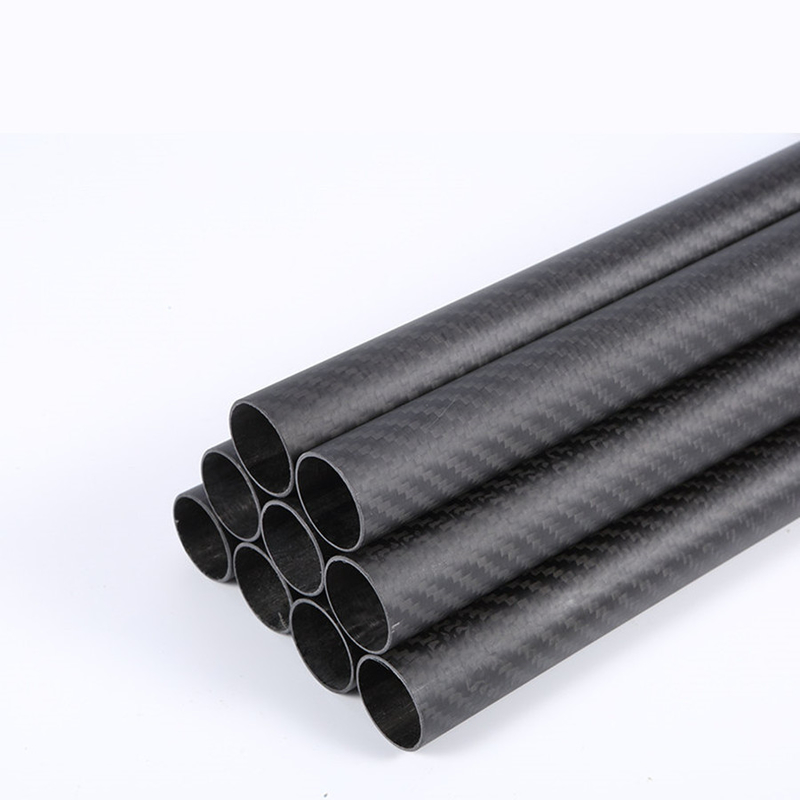

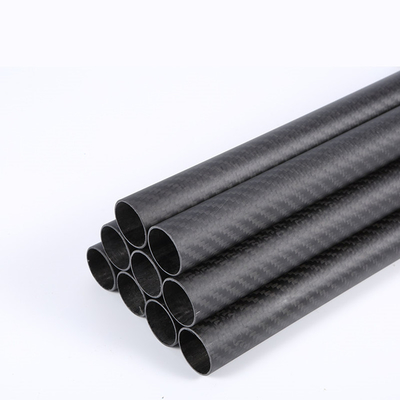

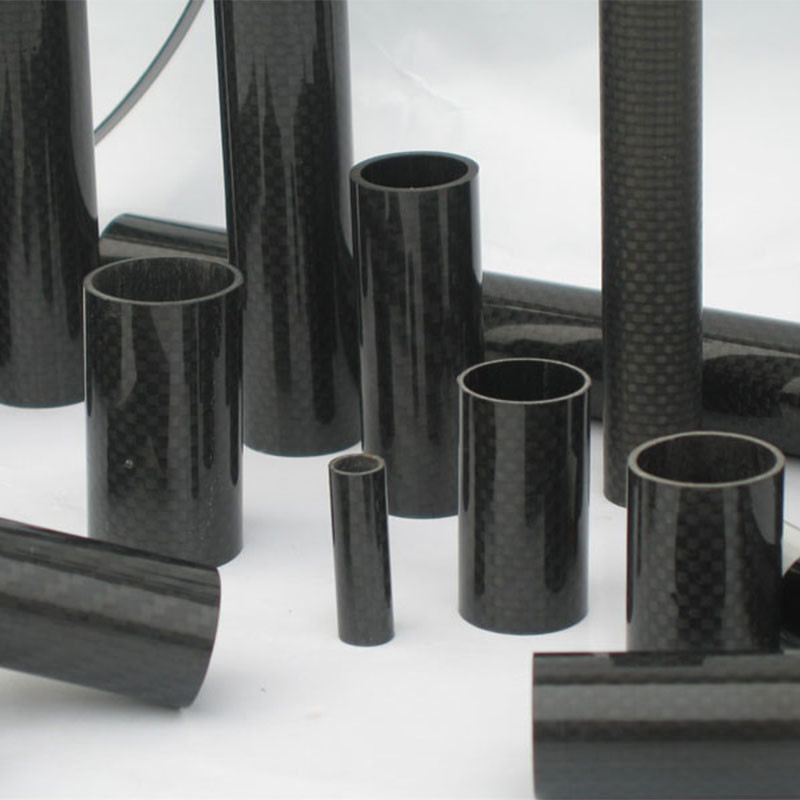

High Quality Roll Wrapped 3K Twill Weave Carbon Fiber Tube Pipe

Carbon fiber has the best combination of high strength, high stiffness, and lightweight. Our carbon fiber tube is as strong as steel, as stiff as aluminum, and lighter than titanium. Carbon fiber tubes can replace metal tubes in many applications. We offer a wide range of tubes to fit your needs.

Carbon Fiber Tube Features:

- High strength and stiffness to weight

- Excellent resistance to fatigue

- Dimensional stability: Low CTE (Coefficient of Thermal Expansion)

- Resistance to corrosion

- X-Ray transparency

- Chemical resistivity

Carbon Fiber Tube Specifications:

We have been engaged in the production of fiber materials for more than 10 years and have a strong engineering team. We will formulate complete solutions for customers from multiple perspectives such as product transportation, installation, maintenance, and cost-effectiveness according to the use conditions and performance requirements of the products.

Carbon Fiber Tube Manufacturing Process:

4-Axis braiding is a process in which we braid carbon fibers over a mandrel. The braiding machine stays in one place and an aluminum mandrel traverses inside of the braiding hoop. The layer of braid is then wet-out with epoxy resin at a 2nd stage in the machine. The laminate is then consolidated and cured at 280F.

- Braided composite structures offer extreme durability and toughness due to the interlocking fibers and no seams.

- If damage does occur, it does not tend to propagate within the structure.

- Typically braided carbon tubes have approximately 75% of fibers directly on the axis of the tube. These fibers are continuous fibers from one end of the part to the other. 10 % of the fibers are +/- 45 deg and around 15% are 90 deg (hoop)

- We can make some adjustments to the percentages of fiber orientation; however, it is not possible to get high percentages of +/- 45 deg.

- The inherent high percentage of fiber on the 0 axis makes a braided tube a very good compression or bending tube.

- Because the machine stays in one place and the mandrel traverses, there is no length limitation to the parts that can be built (the building length, oven length, and mandrel lengths are limiting factors, but the process itself is not limited).

- We typically braid longer-length parts or larger manufacturing runs compared to pre-preg.

- Braided carbon fiber tubes tend to have more surface ripples and small voids in the laminate. This is not a structural issue but it can be a cosmetic issue and it may have an effect on the OD tolerance of the part.

Examples of some applications for braided tubing

Communications towers, large antenna assemblies, portable antennas, drone wing spars, aircraft structural tubing, sailboat spars, truss tubing, reinforcing tubes, spacer tubes, stiffening tubes, compression struts, GPS towers, high tension cable struts, awning support tubes, structural beams, low interference towers.

| Material |

Carbon Fiber Tube Pipe |

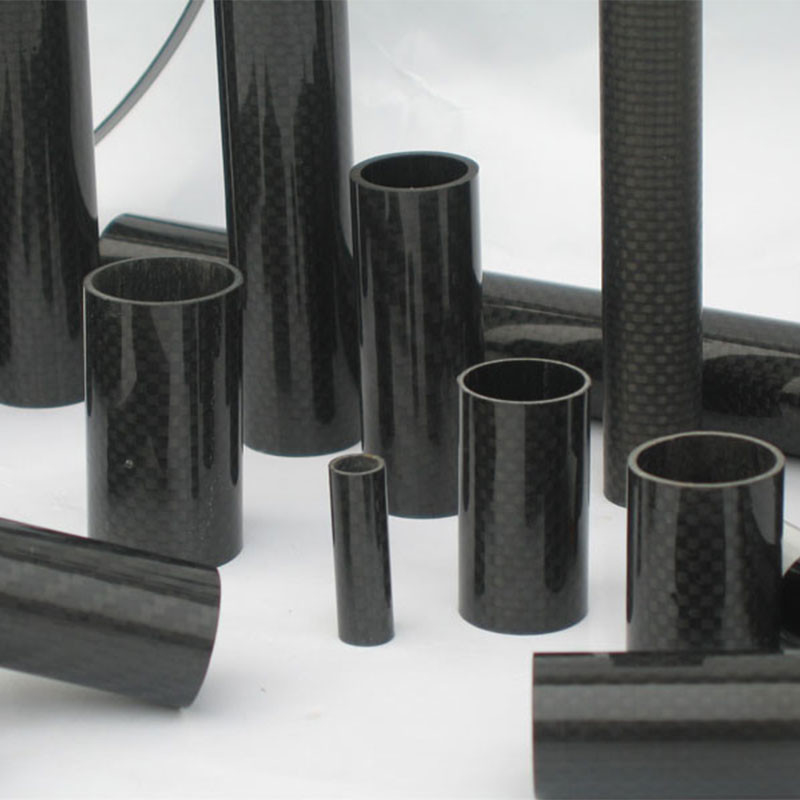

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer, welcome to visit our factory!

Q: Can I have a sample order?

A: Yes, we welcome sample orders to test and check quality. Mixed samples are acceptable too.

Q: What is the lead time?

A: Standard size Sample needs 5 days, mass production needs 15-30 days, according to the quantity

Q: Do you offer OEM service?

A: We accept OEM orders for all our production lines, including the client's logos and labels. After many years of exploration and development, we are sure we can meet all your requirements.

Q: How long can I get a response after I send an inquiry?

A: We will reply to each inquiry within 12 hours.

Q: Your quotation does NOT meet my target price

A: We can propose materials, accessories, or design alternatives to lower the price of your project

Q: What is carbon fiber used for?

A: Carbon fiber -- sometimes known as graphite fiber -- is a strong, stiff, lightweight material that has the potential to replace steel and is popularly used in specialized, high-performance products like aircraft, race cars and sporting equipment.

Q: Is carbon fiber stronger than steel

A: Carbon fibers are classified by the tensile modulus of the fiber. ... Thus, the strongest carbon fibers are ten times stronger than steel and eight times that of aluminum, not to mention much lighter than both materials, 5 and 1.5 times respectively.

Q: Why is carbon fiber so expensive?

A: Another carbon fiber cost factor is energy. ... It takes a lot of energy to reinforce each fiber with carbon atoms. Energy, is also required to bundle the carbon together into fibers and threads. Energy costs are probably the most expensive factor in carbon fiber manufacturing.

Q: What are the advantages and disadvantages of carbon fiber?

A: Carbon fiber reinforced polymer (CFRP) materials possess good rigidity, high strength, low density, corrosion resistance, vibration resistance, high ultimate strain, high fatigue resistance & low thermal conductivity. They are bad conductors of electricity and are not magnetic.

Q: Is carbon fiber resistant to water?

A: The carbon fiber in the composite does not absorb water from the environment, and its resistance remained unchanged when immersed in water.

Q: Is carbon fiber the future?

A: The future of carbon fiber is undoubtedly on a positive course. However, the speed at which carbon fiber integrates into larger commercial markets and more and more common applications is largely dependent on the capabilities of existing carbon fiber manufacturers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!