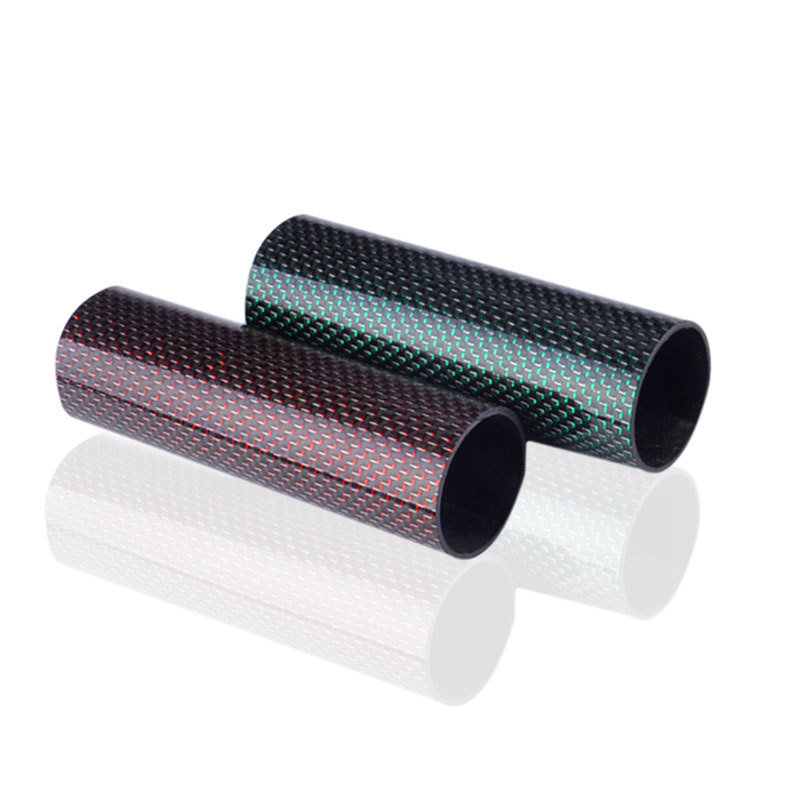

Our Carbon Fiber tubes are designed for the best strength to weight ratio. We use a full wrap of 3K filament fabric impregnated with strong clear epoxy, then a fine gloss or matte finish is added. There are no fillers! These Carbon Fibre tubes provide a perfect balance between strength, stiffness and weight. This results in a very light tube, strong enough for Multi-copter design and their numerous crashes. Also the twill design prevents damage from twisting of the tube, enabling these tubes to handle heavier loads. These tubes are very different from the common "kite" tubes.

Ideal for handling the pressure of motor blocks, preventing rotation failure and crushing of arms in multi-copter drone builds.

Properties and Benefits of Carbon Fiber Tubes

Strength-to-Weight Ratio

One of the most significant advantages of carbon fiber tubes is their exceptional strength-to-weight ratio. Carbon fiber tubes are known to be up to five times stronger than steel while weighing only one-fifth as much. This makes them ideal for applications where weight savings are crucial without compromising structural integrity. The specific strength (strength per unit density) of carbon fiber tubes can reach values around 1500 kNm/kg, significantly higher than that of traditional materials like aluminum and steel. This property is particularly beneficial in industries such as aerospace, automotive, and sporting goods, where reducing weight can lead to enhanced performance and fuel efficiency.

Moreover, carbon fiber tubes can be customized to achieve even higher specific strengths for advanced applications, such as in the construction of space structures or high-performance sports equipment. The ability to combine different fiber orientations within a single tube can enhance specific properties like torsional strength or impact resistance. For example, hybrid carbon fiber tubes, which incorporate other high-strength materials such as Kevlar, can achieve tensile strengths up to 4.0 GPa, making them suitable for extreme environments and high-stress applications. The density of carbon fiber tubes typically ranges from 1.5 to 1.6 g/cm³, contributing to their lightweight nature and ease of handling.

Corrosion Resistance

Carbon fiber tubes exhibit excellent resistance to corrosion, unlike metals such as steel and aluminum, which can degrade over time when exposed to moisture and chemicals. This corrosion resistance makes carbon fiber tubes ideal for use in harsh environments, including marine, industrial, and chemical processing applications. The inert nature of the carbon fibers and the stability of the epoxy resin matrix contribute to this resistance, ensuring long-term durability and reduced maintenance costs. Carbon fiber composites maintain their structural integrity and performance in environments where metals would fail, contributing to longer service life and lower lifecycle costs.

The high corrosion resistance of carbon fiber tubes also translates into significant cost savings over the lifecycle of a product. For instance, offshore oil and gas platforms use carbon fiber tubes for risers and other structural components to avoid the frequent and costly maintenance required for steel alternatives. The annual maintenance cost for steel risers can exceed $100,000, whereas carbon fiber risers require minimal upkeep, potentially reducing maintenance costs by up to 80%.

Furthermore, the non-reactive nature of carbon fiber makes it an ideal choice for biomedical applications, where biocompatibility and resistance to body fluids are essential for long-term implants and prosthetics. Carbon fiber composites do not elicit immune responses, making them suitable for medical implants such as prosthetic limbs and spinal rods. The chemical inertness of carbon fiber, combined with its mechanical properties, ensures that it can be used in environments where other materials would fail or require extensive protective measures. Carbon fiber's biocompatibility reduces the risk of adverse reactions and extends the lifespan of medical devices and implants, often exceeding 20 years without degradation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!