Product Description

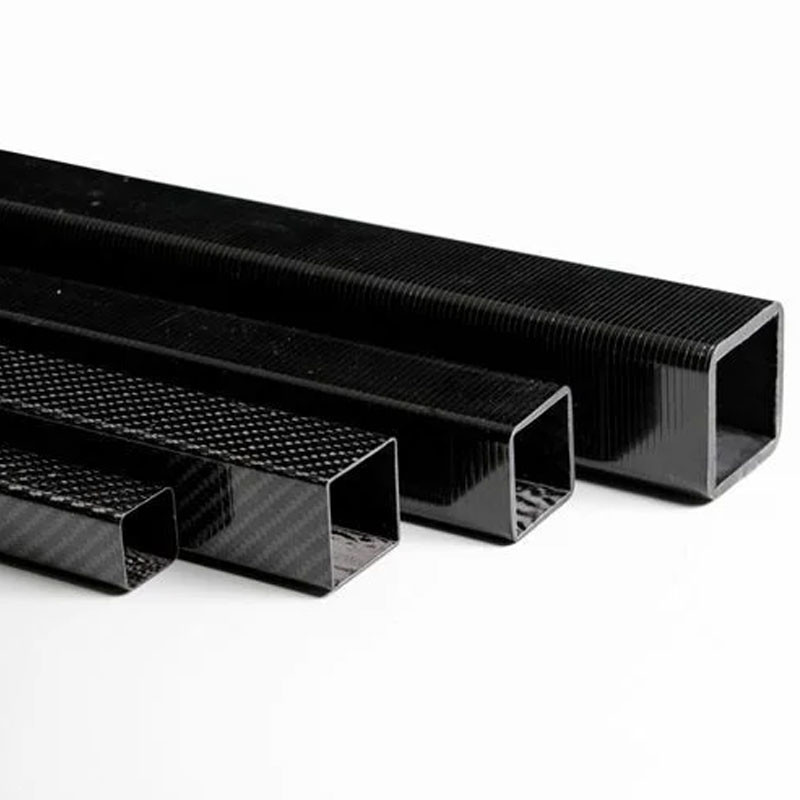

Corrosion Resistance Carbon Fiber Box Sections 100% 3K Square Carbon Fibre Tube

Square tubes, also known as carbon fiber box sections, are optimized for high-performance strength and stiffness. With in-built radiused corners and flat sides, they are ideal for building support systems, lightweight frames, and structures.

If you've got an idea for square carbon tubing and know your specifications, choose your specs from the table below and get in touch.

About our products

- Wall thickness will depend on individual requirements.

- The corner radius will increase with wall thickness.

- Standard walls range from 1.4 - 6.0mm; a price range (per meter) is shown for those thicknesses

- Some over-run stock tubes can be ordered in smaller amounts and are available in specific sizes (quantities available vary constantly).

- Wall thicknesses above 6.0mm or alternative laminate and carbon fiber orientations can be custom-ordered.

Features:

1. Made of high modulus 100% carbon fiber with epoxy resin

2. Great replacement for the low-grade aluminum wing tubes

3. Weights only 1/5 of steel and 5 times stronger than steel

4. Low Coefficiency Of Thermal Expansion, High-Temperature Resistance

5. Good Tenacity, Good Toughness, Low Coefficiency Of Thermal Expansion

Applications:

1. Aerospace, Helicopters Model Drone, UAV, FPV, RC Model Parts

2. Manufacture Fixtures And Tooling, Industrial Automation

3. Sports Equipment, Musical Instruments, Medical Device

4. Building Construction Repair And Strengthening

5. Car Interior Decoration Parts, Art Products

6. Others

Why Choose Us?

*Extensive experience for more than 10+ years

* Professional manufacturer

* Quality materials

* Expert and hard-working workers

* Strict quality control

* High quality is guaranteed

* Reasonable price

Carbon Fiber Tube Manufacturing Process :

4-Axis braiding is a process in which we braid carbon fibers over a mandrel. The braiding machine stays in one place and an aluminum mandrel traverses inside the braiding hoop. The layer of braid is then wet-out with epoxy resin at a 2nd stage in the machine. The laminate is then consolidated and cured at 280F.

Braided composite structures offer extreme durability and toughness due to the interlocking fibers and no seams.

If damage does occur, it does not tend to propagate within the structure.

Typically braided carbon tubes have approximately 75% of fibers directly on the axis of the tube. These fibers are continuous fibers from one end of the part to the other. 10 % of the fibers are +/- 45 deg and around 15% are 90 deg (hoop)

We can make some adjustments to the percentages of fiber orientation; however, it is not possible to get high percentages of +/- 45 deg.

The inherent high percentage of fiber on the 0 axis makes a braided tube a very good compression or bending tube.

Because the machine stays in one place and the mandrel traverses, there is no length limitation to the parts that can be built (the building length, oven length, and mandrel lengths are limiting factors, but the process itself is not limited).

We typically braid longer-length parts or larger manufacturing runs compared to pre-preg

Braided carbon fiber tubes tend to have more surface ripples and small voids in the laminate. This is not a structural issue but it can be a cosmetic issue and it may have an effect on the OD tolerance of the part.

Examples of some applications for braided tubing

Communications towers, large antenna assemblies, portable antennas, drone wing spars, aircraft structural tubing, sailboat spars, truss tubing, reinforcing tubes, spacer tubes, stiffening tubes, compression struts, GPS towers, high tension cable struts, awning support tubes, structural beams, low interference towers.

| Material |

Square Carbon Fibre Tube |

| Shape |

Rectangular or Custom |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!