Product Description

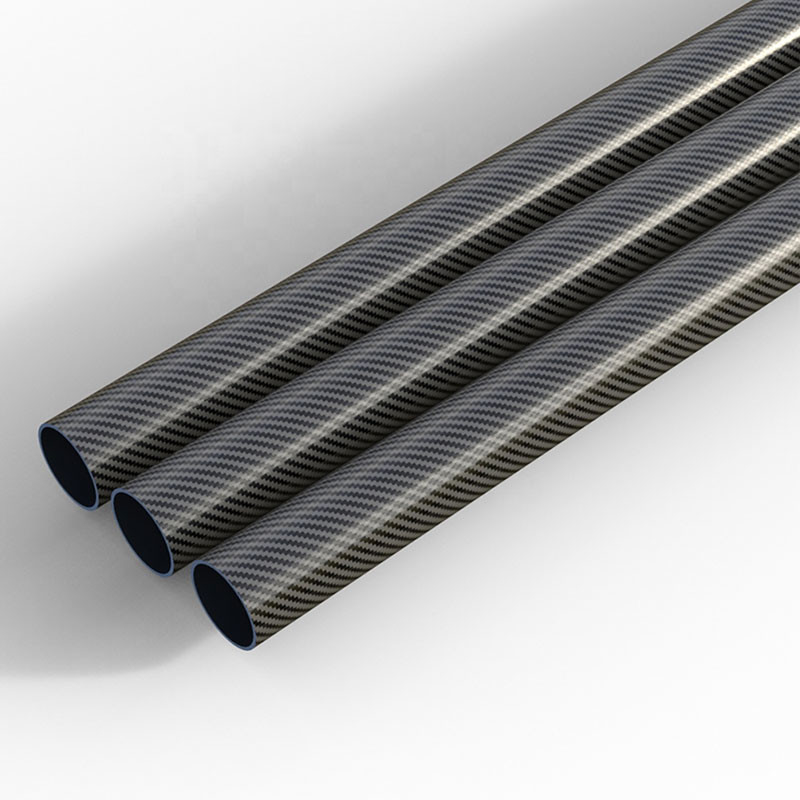

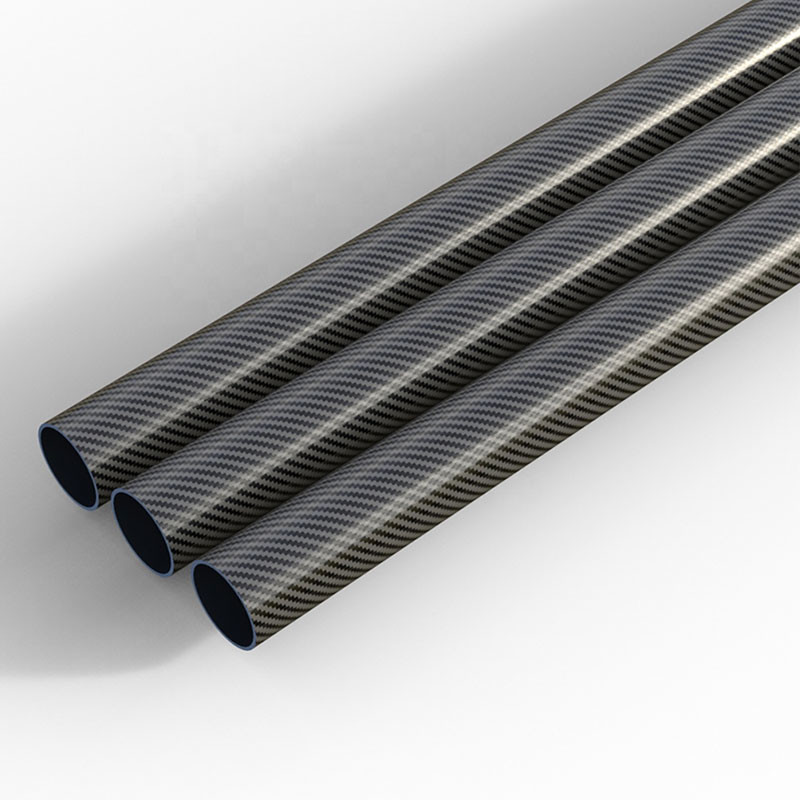

Strong Corrosion Resistance 3K Carbon Fibre Pipe wound ± 45°, plain weave (3k)

Roll wrapped carbon fibre tubes with a smooth surface finish of 3k carbon fabric prepreg in plain weave, clear-coated glossy. Subjacent layers from unidirectional non-crimp fabric. High-quality epoxy resin matrix.

Characteristics:

Lightweight, excellent corrosion and heat resistance and electrical conductivity. Very good torsional and hoop stiffness, but lower bending strength than other tubes.

After laminating, the wound CFK round tubes are ground (round) to size and then coated.

How strong is carbon fiber tubing?

Carbon fiber is very strong, very stiff, and relatively light. The stiffness of a material is measured by its modulus of elasticity. The modulus of carbon fiber is typically 34 MSI (234 Gpa). The ultimate tensile strength of Carbon Fiber is typically 600-700 KSI (4-4.8 Gpa).

Application:

1. RC Toy model, Aeromodelling, Helicopter Model.

2. Electrical products.

3. Shipbuilding.

4. Space aviation defense.

5. Sports equipment.

6. Automobile parts.

7. Wind power blades.

8. Spinning Reels Brake Rotor friction plate, Rocker.

9. Medical device(X-ray, DR).

10. Etc.

Which is stronger carbon fiber or steel?

Though steel is generally considered the standard when it comes to construction and industrial settings, in terms of strength to weight ratios, carbon fiber is actually significantly stronger than steel. In this application, “strength” is defined by a material's resistance to deformation or “modulus of elasticity”.

Why choose us:

- Over many years of rich experience in the field of carbon/aramid/UHMWPE fibers and relative products.

- Having over 50 firm&faithful suppliers which offer good prices and stable good quality.

- Providing constructive suggestions on the products to clients and help them to find a total solution.

We supply competitive prices, high quality, and satisfactory service!

You will find we are the right supplier you are looking for!

Features

- Lightweight, high strength, transportation, and construction and installation are very convenient, compared with plastic products, the strength is tens times.

- Corrosion resistance, anti-aging, long service life, and have better water resistance and aging resistance.

- The security is good, the impact is high, the design is strong, is the modern industrial and agricultural products, one of the indispensable new alternative materials.

Specifications:

| Product Name |

Carbon Fibre Tube |

| Material |

100% Carbon Fiber |

| Color |

Black or custom |

| Surface |

Matt/Glossy |

| Size |

Custom thickness and length |

| Fiber Specifications |

1K/3K/12K |

| Weaving Style |

Plain/Twill |

| Fiber Type |

1.Carbon fiber+carbon fiber

2.Carbon fiber+ glass fiber

3.Carbon fiber+aramid fiber |

| Application |

1. Aerospace, RC model parts Helicopters Model

2. Manufacture fixtures and tooling

3. Industrial automation and robotics

4. Sports equipment

5. Musical instruments

6. Scientific apparatus

7. Medical device

8. Others |

| Our Product |

Carbon fiber tube, carbon fiber plate, carbon fiber profiles. |

FAQ:

Q1: Can I have a sample order?

A: Yes, you are welcome place a sample order to test and check quality your side before you place the bulk order. Mixed samples are also acceptable. Please let us know your courier account number to deliver it freight collected.

Q2: What is the lead time of an order?

A: For our standard product, sample order only needs 1-3 days, mass production usual needs 10-15 days but it’s according to the order quantity.

Q3: Do you have any MOQ limit?

A: Yes, we have different MOQ limit according to the type of product you want, but usually MOQ is small.

Q4: Can you accept mixed batch of different products?

A: Yes, we support different products mixed.

Q5: How do you ship the goods?

A: We can ship the goods by sea, air, train or courier.

Q6: Can you pack the goods on pallet or in crate?

A: Yes, we can provide such kind of package to facilitate loading and unloading the goods by forklift.

Q7: Can you print our logo on the outer package?

A: Yes, we can, but it’s only for big order, for small order, we just print it on the paper and paste it on the package.

Q8: Can we visit your company and factory?

A: Yes, you are welcome, if you need the airport pick up and hotel reservation, please let us know once you decide the itinerary.

Q9: What is your payment terms?

A: As usual, you are suggested to send the payment by t.t, 100% t.t in advance for order value less than $5000, for bigger order, it’s 30% deposit and 70% t.t against B/L copy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!