Product Description

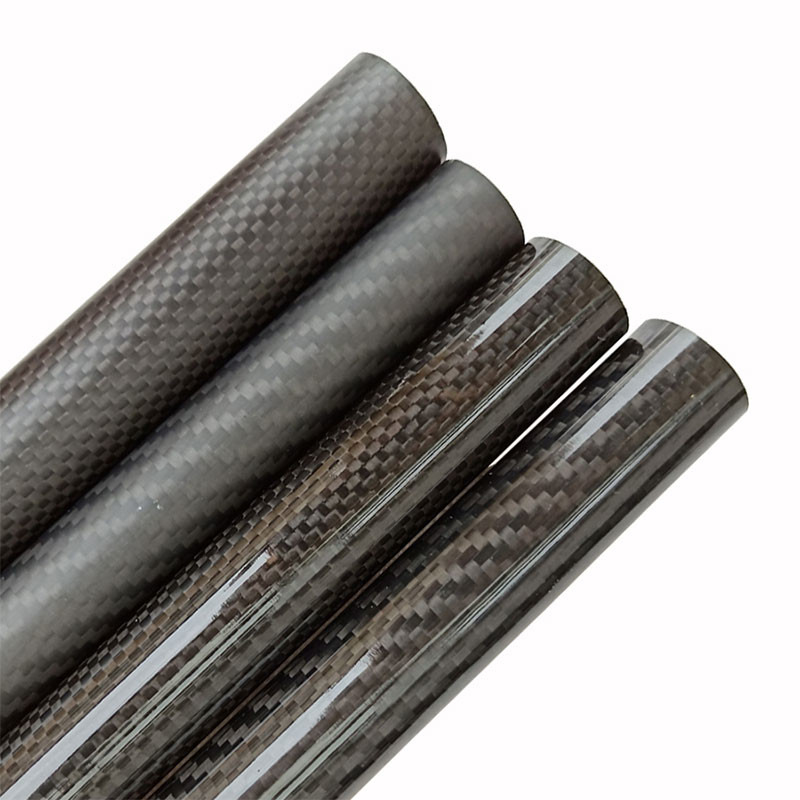

High Pressure Resistance Carbon Fiber Tube Good Flexibility 100% 3K CF Tubes

LIJIN manufactures custom carbon fiber pultrusions to fit your strength, stiffness, and geometric requirements. Our products can be used as fishing poles, paddles, arrow shafts, alpenstocks, etc.

Strength, Stiffness, and Comparisons With Other Materials

Carbon fiber is extremely strong. It is typical in engineering to measure the benefit of a material in terms of strength to weight ratio and stiffness to weight ratio, particularly in structural design, where added weight may translate into increased lifecycle costs or unsatisfactory performance. The stiffness of a material is measured by its modulus of elasticity. The modulus of carbon fiber is typically 33 msi (228 GPa) and its ultimate tensile strength is typically 500 ksi (3.5 Gpa). High stiffness and strength carbon fiber materials are also available through specialized heat treatment processes with much higher values. Compare this with 2024-T3 Aluminum, which has a modulus of only 10 msi and ultimate tensile strength of 65 ksi, and 4130 Steel, which has a modulus of 30 msi and ultimate tensile strength of 125 ksi.

Steel will permanently deform at a stress level below its ultimate tensile strength. The stress level at which this occurs is called the yield strength. Carbon fiber, on the other hand, will not permanently deform below its ultimate tensile strength, so it effectively has no yield strength.

As an example, a plain-weave carbon fiber reinforced laminate has an elastic modulus of approximately 6 msi and a volumetric density of about 83 lbs/ft3. Thus the stiffness to weight for this material is 107 ft. By comparison, the density of aluminum is 169 lbs/ft3, which yields a stiffness to weight of 8.5 x 106 ft, and the density of 4130 steel is 489 lbs/ft3, which yields a stiffness to weight of 8.8 x 106 ft.

Hence even a basic plain-weave carbon fiber panel has a stiffness-to-weight ratio 18% greater than aluminum and 14% greater than steel. The utilization of prepreg, and in particular high modulus and ultra high modulus carbon fiber prepregs, yields substantially higher stiffness to weight ratios. For example, a panel comprising a 0/90 layup of standard modulus prepreg carbon fiber will have a bending modulus of about 8 msi, or about 30% more rigid than non-prepreg options.

For very demanding applications where maximum stiffness is required, 110 msi ultra high modulus carbon fiber can be used. This specialized pitch-based carbon fiber has a bending stiffness over 3 times that of a standard modulus prepreg panel (about 25 msi). When one considers the possibility of customized carbon fiber panel stiffness through strategic laminate placement, a panel (or other cross-section, such as a tube) can be fabricated with bending stiffness on the order of 50 msi.

Testing performed by LIJIN has demonstrated all zero-degree oriented uni-directional ultra high modulus coupon samples to have tensile stiffness in excess of 75 msi, or over twice the stiffness of steel, yet still only half the weight of aluminum. Using the aforementioned comparison, the stiffness to weight ratio of this material is then over 10 times that of either steel or aluminum. When one includes the potentially massive increases in both strength to weight and stiffness to weight ratios possible when these materials are paired with lightweight honeycomb and foam cores, is it obvious the impact advanced carbon fiber composites can make on a wide variety of applications.

| Name |

Durable Carbon Fiber Tube |

| Feature |

1. Made of high modulus 100% carbon fiber |

| 2. Great replacement for the low-grade aluminum wing tubes |

| 3. Weights only 1/5 of steel and 5 times stronger than steel |

| 4. Low Coefficiency Of Thermal Expansion, High-Temperature Resistance |

| 5. Good Tenacity, Good Toughness, Low Coefficiency Of Thermal Expansion |

| Specification |

Pattern |

Twill, Plain |

| Surface |

Glossy, Matte |

| Line |

3K Or 1K,1.5K, 6K |

| Color |

Black, Gold, Silver, Red, Bue, Gree(Or With Color Silk) |

| Material |

Japan Toray Carbon Fiber Fabric+Resin |

| Carbon Content |

68% |

| Size |

Type |

ID |

Wall thickness |

Length |

| Round Tube |

6-60 mm |

0.5,0.75,1/1.5,2,3,4 mm |

1000,1200,1500 mm |

| Square Tube |

8-38 mm |

2,3 mm |

500,600,780 mm |

| Application |

1. Aerospace, Helicopters Model Drone, UAV, FPV, RC Model Parts |

| 2. Manufacture Fixtures And Tooling, Industrial Automation |

| 3. Sports Equipment, Musical Instruments, Medical Device |

| 4. Building Construction Repair And Strengthening |

| 5. Car Interior Decoration Parts, Art Products |

| 6. Others |

| Packing |

3 layers of protective packaging: plastic film, bubble wrap, carton |

| (Normal size: 0.1 * 0.1 * 1 meter(width*height*length) |

Uses Include:

- Aerospace Spars & Beams

- UAV Housing Components

- Frames & Supports

- Structural Components

- Interior Design

- Automation Equipment

- Recreational Equipment

Our advantages:

- Good production capacity, prompt delivery

- Specification can be customized

- Strict quality control system in every production process

- 24 hours service, quick reply

- Small order accepted

- Perfect after-sales service, free sample is available

- Customized Service

Frequently Asked Questions About Carbon Fiber Tubes

1. What’s the feature of your product?

There are many good characteristics of our carbon fiber product, such as lightweight, high strength, durable, and fashion, etc.

2. Can I have a sample order?

Yes, we welcome sample orders to test and check quality. Mixed samples are acceptable. For some products, we can offer free samples. Clients just need to bear the shipping cost.

3. What is the lead time?

The sample needs 1-3 days, mass production depends on order quantity. Normally 6-9 days.

4. Can you accept the mixed batch of different products?

Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc.

5. What file need if need to do CNC Cutting or molding products?

We Need CAD DXF or DWG files for CNC cutting, 3D, STEP, STP, IGS Files for molding.

6. How do we do quality control?

We have inspectors to check each procedure to avoid any mistakes.

7. How do you pack the goods?

We wrap the goods with soft plastic bags first and then pack them using a cardboard box with foam board inside.

8. How is your after-sale service?

We provide our clients with excellent after-sale service including logistics tracking, application guide, problem solution,

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!