Product Description

Small Tolerance Range 100% 3K Roll Wrapped Round Carbon Fiber Tubes

LIJIN Composites is able to provide an extensive range of high performance, light weight composite tubing for use in a wide variety of industries and applications. Our assortment of composite tubes are manufactured through roll wrapping, pultrusion, or filament winding processes in the most popular composite materials such as carbon fiber, fiberglass, and Kevlar®. Available in standard and custom sizes, our lightweight, composite tubes exhibit outstanding strength, durability and rigidity. They deliver excellent tensile strength characteristics compared to conventional structural metals, and are a first choice in a variety of performance applications.

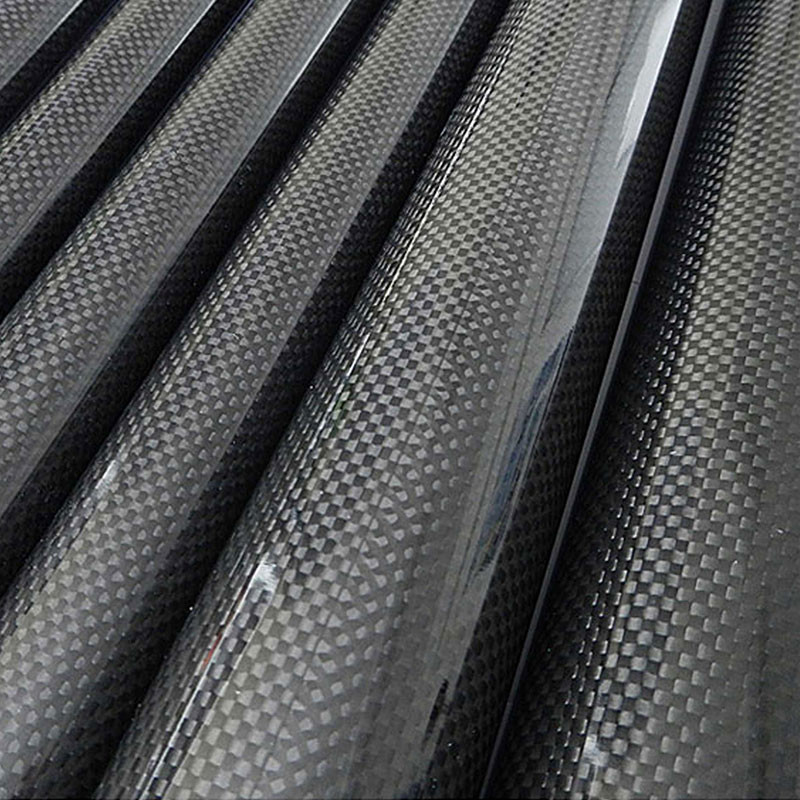

All our carbon tubes in this section are roll wrapped using high grade carbon pre-preg, in a 2 x 2 twill weave pattern. Pre-preg is rolled onto a mandrel and placed in an oven to cure, resulting in a tube that is stiff and light.

These tubes can be used for robotics, UAV construction, leisure applications and anywhere that requires low weight but high stiffness.

Tubes can be cut and shaped with basic hand tools, such as a fine tooth hacksaw. All tubes will be shipped in postal tubes to prevent crushing during transit.

Features:

- Light Weight – Less Density – 20% Of Steel

- High Strength

- High Corrosion Resistance

- Superior Dimensional Stability

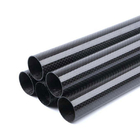

- Consistent Cross Section

- Lasting Performance

- Excellent Structural Properties

- Environmentally Safe

- Non-Magnetic Electromagnetic

- Ease Of Fabrication & Installation

Applications:

- Automotive

- Light Aircraft Tubing

- Construction

- Duct rod / Fish rods

- Aerospace Instrument & Interior Supports

- Photography & Sound Booms

- Outer Space & Terrestrial Antennae Supports

- Corrosion Resistant Equipment Marine

- Sporting Goods

- Robotic Arms & Supports

- Advertising Panels

- Lifting Spars

How to Cut and Shape

They can be cut with a fine band saw, hacksaw, or dremel tool. Enhanced Composites roll wrap carbon fibre tubes are manufactured using an epoxy matrix, therefore they will easily bond with other epoxy resins.

Typical Uses

Roll wrapped tubes are better for applications where the tube may be subject to a variety of forces including bend, twist and crush. These light 10mm tubes are suitable for demanding engineering applications including scale aircraft, gliders, helicopter U.A.V.’s, lightweight frames or structures, tubular vessels, poles, column supports or any construction that requires strength, rigidity and lightness yet appearance is also important. They are equally suited to other precision applications like robotics and automation.

Tubes made with epoxy resin systems have virtually zero water absorption making them suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

| Material |

Straight Carbon Fiber Tube |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Our Service:

1. It ensures that a year of quality assurance and 24 hours online customer service.

2. Protection of your sales area, ideas of design, and all your private information.

3. Request for samples is accepted.

4. Drilling and slotting are accepted.

5. We guarantee the products to be manufactured with the finest materials and mature technics.

All tubes can be repaired at no charge if returned to us, postage prepaid, within one year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!