Product Description

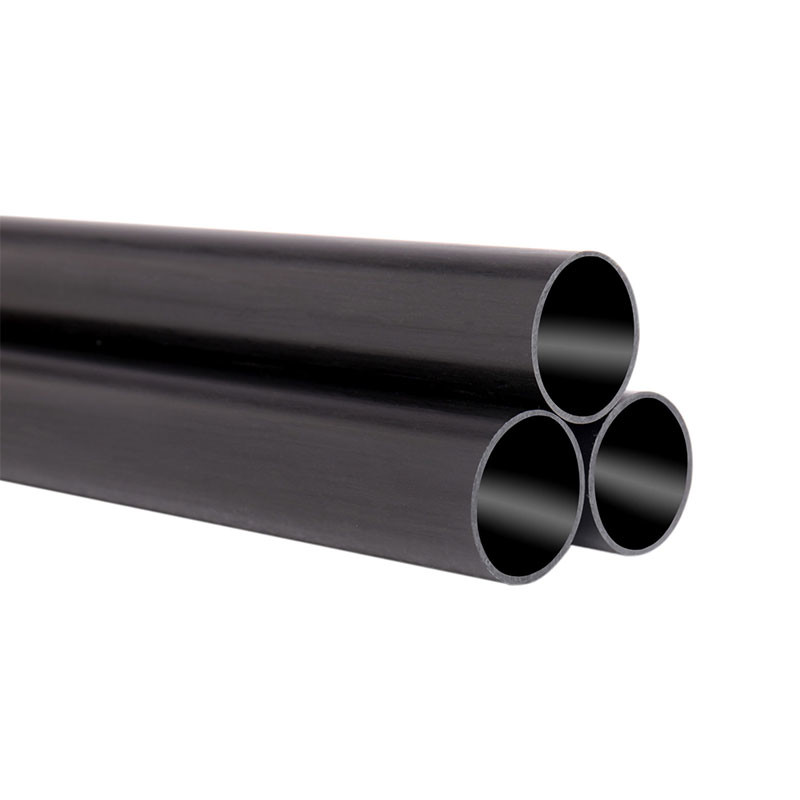

Roll Wrapped Carbon Fiber Tube, Lightweight Pultrusion Carbon Fiber Tube

Pultruded carbon tubes are created by pulling linearly-oriented carbon fibers through a resin bath and then a series of tooling to create the specified inner and outer diameters of the tube. The carbon tube is then heated to cure it. Carbon tubes are especially stiff longitudinally, due to the unidirectional orientation of the fibers.

This type of profile has a high specific mechanical resistance (related to its weight), lightness, rigidity, great resistance to fatigue and vibrations, resistance to oxidation and corrosion, low coefficient of thermal expansion and durability.

Pultrusion is a technique of continuous production of linear profiles with a constant section. This process has many similarities to extrusion, the main difference is in the feeding system: in extrusion the material is pushed through the matrix (mould), in pultrusion it is extracted from the matrix. This procedure does not allow variations in shape, sections or curves. Products that can be obtained by this process can have sections or thicknesses of up to approximately 15mm, with epoxy resins and up to 70 mm with polyester resins.

Products made with this technology have excellent tensile strength properties due to the linear orientation of the fibres in the direction of axis of the profile; if it is also necessary to have a good transversal resistance, a woven fabric is used as a backing in specific quantities and weights.

Pultrusion is the name given to the continuous process of manufacturing composite materials and generally produces sections including tube, rod, box and angle with unidirectional alignment of the fibres.

Because they are pultruded, the carbon fibre tubes in this section have unidirectional fibre alignment which gives them the maximum possible strength along their length but leaves them less strong in other planes meaning that particular care needs to be taken to how the are fixed to reduce crush forces and spread any load as evenly as possible.

Carbon Tubes are the ultimate push rods since they contain 95% unidirectional carbon fiber running longitudinally and are covered with a light glass scrim. Our tubes are manufactured in a pultrusion process. This design offers a high stiffness to weight ratio.

| Material |

Pultrusion Carbon Fiber Tube |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Our Service:

1. It ensures that a year of quality assurance and 24 hours online customer service.

2. Protection of your sales area, ideas of design, and all your private information.

3. Request for samples is accepted.

4. Drilling and slotting are accepted.

5. We guarantee the products to be manufactured with the finest materials and mature technics.

All tubes can be repaired at no charge if returned to us, postage prepaid, within one year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!