Product Description

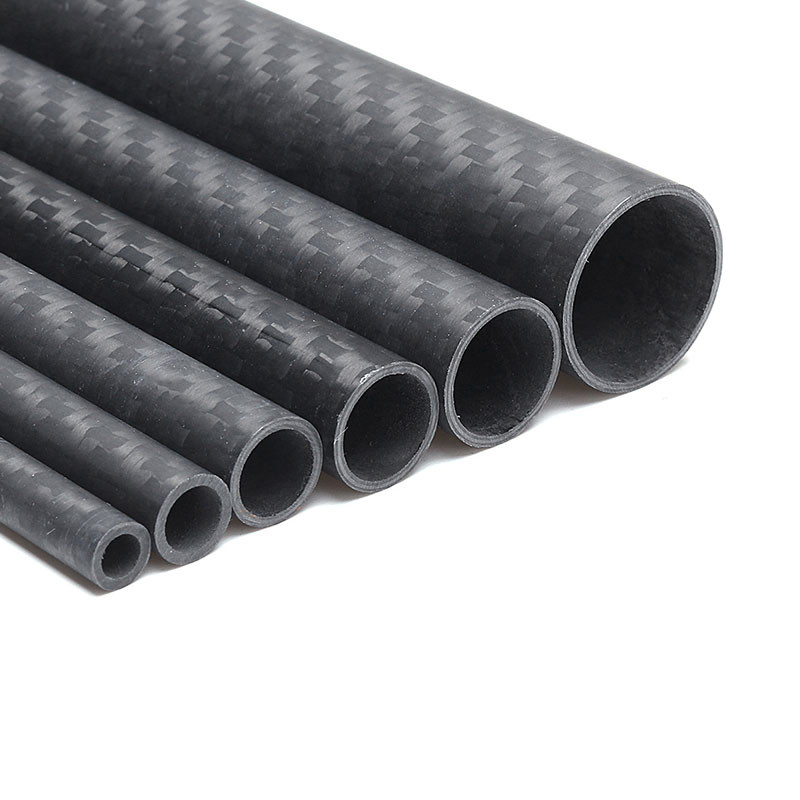

Common 3K Twill Real Carbon Fiber Hose Straight Carbon Fiber Tube

The first use of carbon fiber in high performances goes back to 1960-1970. It became popular very quickly in every technical area where lightness and strenght were primary requirements.

Carbon fiber originates from thermal pyrolysis in a controlled oven where a material called precursor is strongly warmed up at a temperature of about 2000° C in an inert gas atmosphere to produce graphite.

Then other heat treatments modify the final properties of the fibers, for example warming up at temperatures lower than 2000°C gives you a more strenght material, whereas with higher temperatures you'll get a more expensive carbon fiber but with a higher Elastic Modulus (Young's modulus).

This is why today there are many kinds of carbon fibers that, even if they're similar, leads to products with different prices and performances.

The carbon fibers previously obtained are lately drowned in epoxy resin (called matrix) that acts as a binder, allowding the fibers to work together and to distribute the strain uniformly to each one of them.

As you can guess this matrix has a primary role and it has been studied and improved in the last years, like the nanocomposite fillers inside of it.

So the carbon fibers drowned in the matrix become to all intents and purposes a composite material like the reinforced concrete, where the final mechanical features are higher than the ones of the constituents materials.

Features:

- Light Weight – Less Density – 20% Of Steel

- High Strength

- High Corrosion Resistance

- Superior Dimensional Stability

- Consistent Cross Section

- Lasting Performance

- Excellent Structural Properties

- Environmentally Safe

- Non-Magnetic Electromagnetic

- Ease Of Fabrication & Installation

Applications:

- Automotive

- Light Aircraft Tubing

- Construction

- Duct rod / Fish rods

- Aerospace Instrument & Interior Supports

- Photography & Sound Booms

- Outer Space & Terrestrial Antennae Supports

- Corrosion Resistant Equipment Marine

- Sporting Goods

- Robotic Arms & Supports

- Advertising Panels

- Lifting Spars

How to Cut and Shape

They can be cut with a fine band saw, hacksaw, or dremel tool. Enhanced Composites roll wrap carbon fibre tubes are manufactured using an epoxy matrix, therefore they will easily bond with other epoxy resins.

Typical Uses

Roll wrapped tubes are better for applications where the tube may be subject to a variety of forces including bend, twist and crush. These light 10mm tubes are suitable for demanding engineering applications including scale aircraft, gliders, helicopter U.A.V.’s, lightweight frames or structures, tubular vessels, poles, column supports or any construction that requires strength, rigidity and lightness yet appearance is also important. They are equally suited to other precision applications like robotics and automation.

Tubes made with epoxy resin systems have virtually zero water absorption making them suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

| Material |

Straight Carbon Fiber Tube |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

Our Service:

1. It ensures that a year of quality assurance and 24 hours online customer service.

2. Protection of your sales area, ideas of design, and all your private information.

3. Request for samples is accepted.

4. Drilling and slotting are accepted.

5. We guarantee the products to be manufactured with the finest materials and mature technics.

All tubes can be repaired at no charge if returned to us, postage prepaid, within one year.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!