Product Description

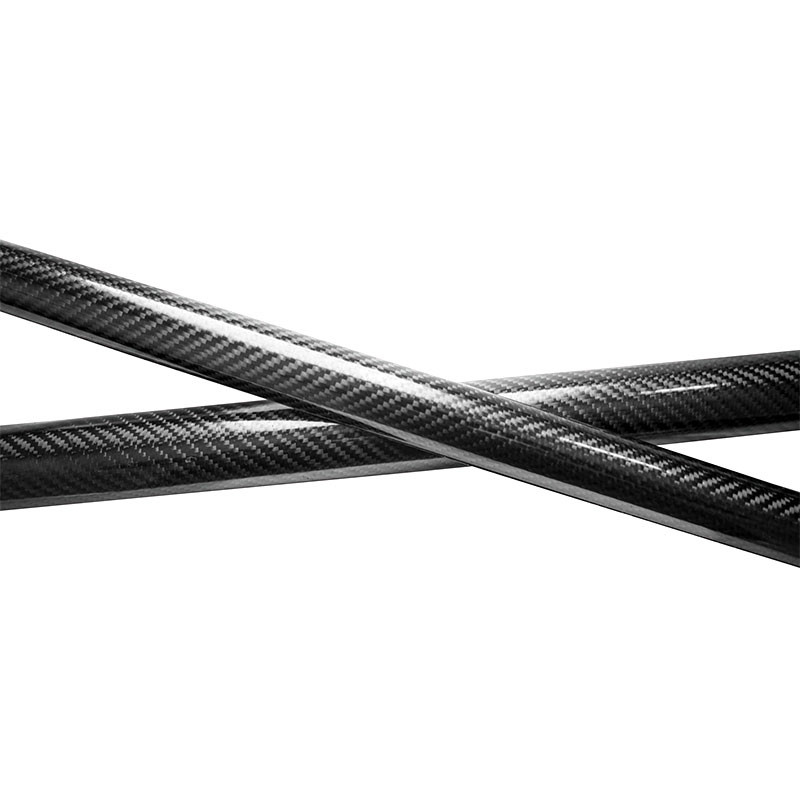

Universally Strong Low Thermal Conductivity Roll Wrap Carbon Fiber Pipe

Roll wrapped prepreg carbon fiber tubes are constructed using multiple wraps of twill and/or unidirectional fabrics. Rolled tubes are ideal for applications that require the highest bending stiffness and lowest weight, such as automation robotics, telescoping poles, idler rollers, and UAV components. The standard finish is cello-wrapped gloss, but a smooth sanded finish is also available.

Roll wrapped carbon fiber tubes are universally strong and can tolerate all forces equally. Unlike pultruded tubes they can withstand twist (torque) force, compression, tension and deflection without splitting. This is because the fibres have been wound around the diameter of the tube as well as running lengthways. First, the tube mandrel is wound with unidirectional carbon fibre around the diameter, then it is wrapped with the fibres running the length (longitudinally), finally, it is finished with a wrap of 3K twill before it is cured in an autoclave, roll sanded and recoated with epoxy.

Features:

- Very precise, cylindrical, manufactured using prepreg wire-wrap process

- Unidirectional fibre with glass scrim weave

- Top layer carbon-roving visual structure - canvas

- External diameter wrapped surface with diameter tolerance ± 0.5 mm

- Surface wrapped structure

- Temperature-resistant up to 120°C

- Outstanding bending resistance

| Material |

Roll Wrap Carbon Fiber Pipe |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

What are the uses of carbon fiber tubes?

Carbon fiber has various excellent properties of elemental carbon, such as low specific gravity, excellent heat resistance, low coefficient of thermal expansion, high thermal conductivity, good corrosion resistance and conductivity. At the same time, it has the flexibility of fiber, which can be used for weaving and winding.

The most excellent performance of carbon fiber is that its specific strength and specific modulus are higher than that of ordinary reinforced fiber. The specific strength and specific modulus of the composite formed by carbon fiber and resin are about three times higher than that of steel and aluminum alloy. Carbon fiber composite pipes are widely used in many fields, which can significantly reduce the weight, improve the payload and performance. They are important structural materials in aerospace industry.

1. Aerospace

Carbon fiber composites have long been used in satellite structures, solar panels and antennas due to their advantages of light weight, high rigidity, high strength, stable size and good thermal conductivity. Nowadays, most of the deployable solar cells on artificial satellites are made of carbon fiber composite materials, and some key parts of space station and space transportation system are also made of carbon fiber composite materials.

Carbon fiber tube is also very good in UAV applications. In practical applications, it can be applied to different parts of UAV body, such as arm, frame and so on. Compared with aluminum alloy, the application of carbon fiber tube in UAV can reduce weight by about 30%, which can improve the load capacity and endurance of UAV. Carbon fiber tube has the advantages of high tensile strength, corrosion resistance and good anti-seismic effect, which can effectively guarantee the life of UAV.

2. Mechanical equipment

Application of carbon fiber composite material in robot end picker the end picker is a kind of fixture used in the transmission process of stamping production line. It is installed on the loading and unloading robot of the press, and drives the end picker to carry the workpiece through trajectory teaching. Among many new materials, carbon fiber composite is the most popular.

The proportion of carbon fiber composite is less than 1 / 4 of that of steel, but its strength is several times of that of steel. The robot end pickup made of carbon fiber composite can reduce the shaking and self burden when handling Automobile parts, and its stability can be greatly improved.

3. Military industry

Carbon fiber has the characteristics of light weight, high strength, high modulus, corrosion resistance, fatigue resistance, high temperature resistance, thermal conductivity, good heat dissipation and low coefficient of thermal expansion. Carbon fiber and its composites are widely used in rocket, missile, military aircraft, personal protection and other military fields, and the amount is increasing with each passing day, which makes the performance of military equipment improve continuously. Carbon fiber and its composites have become important strategic materials for the development of modern defense and military weapons.

In terms of military rockets and missiles, the excellent performance of carbon fiber composite materials has also been better applied and developed, such as "Pegasus", "delta" carrier rocket, "Trident II (D5)," dwarf "missile, etc. carbon fiber composite materials are used; while the U.S. strategic missile MX intercontinental missile, Russian strategic missile" poplar "M Missiles also use advanced composite launchers.

4. Sporting goods

Most of the traditional sports products are made of wood, but the mechanical properties of carbon fiber reinforced composites are much higher than that of wood. The specific strength and specific modulus of carbon fiber reinforced composites are 4 times and 3 times that of Chinese fir, 3.4 times and 4.4 times that of Wutong wood. Therefore, it has been widely used in sports goods, and its consumption accounts for about 40% of the total consumption of carbon fiber in the world. In the field of sporting goods, carbon fiber pipes are mainly used in the following aspects: golf clubs, fishing poles, tennis rackets, badminton rackets, ice hockey clubs, bows and arrows, sailing masts, etc.

Taking the tennis racket as an example, the tennis racket made of carbon fiber composite material is light and strong, with large rigidity and small strain, which can reduce the deviation when the ball is in contact with the racket; at the same time, the CFRP has good damping property, which can extend the contact time between the gut and the ball, so that the tennis ball can obtain greater acceleration. For example, the contact time of wooden racket is 4.33 MS, that of steel product is 4.09 MS, and that of CFRP is 4.66 Ms. the corresponding initial velocity of the ball is 1.38 km / h, 149.6 km / h and 157.4 km / h respectively.

In addition to the above fields, carbon fiber composites are also widely used in rail transit, wind power, medical devices and other fields. With the continuous breakthrough of carbon fiber raw material manufacturing and subsequent processing technology, the price of carbon fiber raw materials is expected to become more people-friendly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!