Product Description

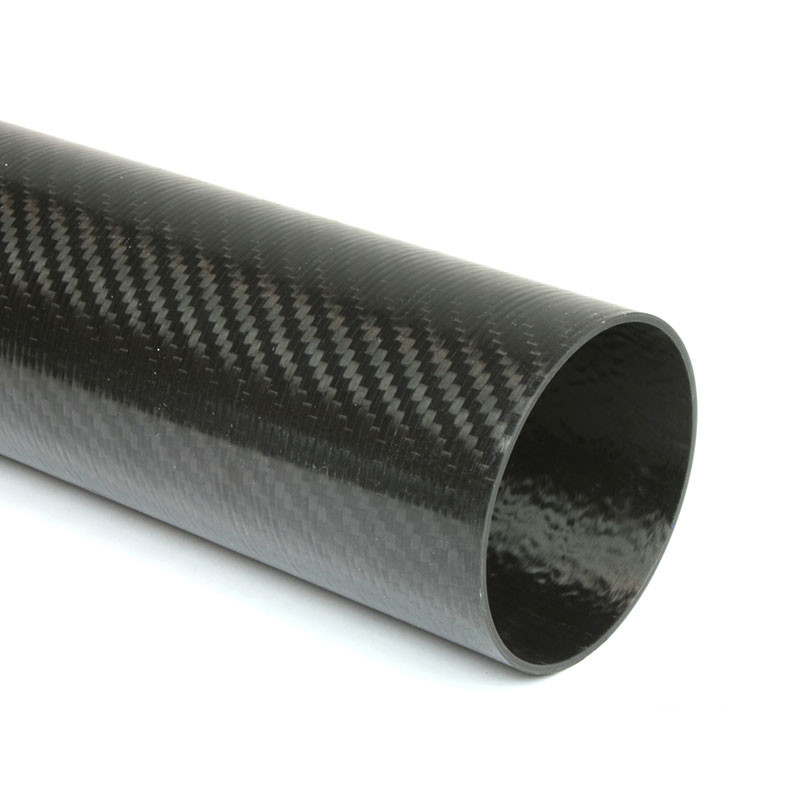

Flexibility Carbon Fiber Pole - Absolutely Fits - 100% Carbon - Highest Quality

Quality and Performance Guaranteed

At LIJIN Composites we understand that mechanical, physical, and thermal property prediction is vital to the uptake of new and unfamiliar materials and manufacturing technologies into any industry. Basic requirements for all new materials are that they can be modeled and their performance predicted effectively. We can support you through stress analysis on your composite project using the latest software & techniques that are widely utilized for advanced composites in the aerospace industry. We can assist with your structural model, setting boundary conditions, load cases, and applicable material allowable (strength, strain) in order to provide a robust analysis of how a particular panel might behave in service.

We have an established Quality Policy to ensure the quality & performance of our products, where many of our advanced composite sheets & panels come with a technical datasheet.

Product Description

LIJIN offers a wide selection of carbon fiber reinforcements. We take great measures to ensure that all of the products we handle are First Quality, manufactured to the highest standards for maximized strength and perfect cosmetics.

No matter what carbon fiber product you select, it should always be used with a resin system. When combined, they will produce hard, reinforced parts—even complex shapes.

- Material: 100% 3K Pure Carbon Fiber

- Length: 500mm/ 0.5meter/ 19.7inch, etc.

- Size: 8*10mm, 10*12mm, 12*14mm, 14*16mm, 16*18mm, 18*20mm, 20*22mm, 21*23mm, 22*24mm, 24*26mm, 26*28mm, 28*30mm, multiple size for pick.

- Thickness wall: 1mm, etc.

- Optional Color: Red carbon fiber tube, Blue carbon Fiber tube, Sliver carbon fiber tube

- Using for: Airplane, helicopter, multi-copter, OR other you's like.

Features

- Lightweight, high strength, transportation, and construction and installation are very convenient, compared with the plastic products, the strength is tens times.

- Corrosion resistance, anti-aging, long service life, and have better water resistance and aging resistance.

- The security is good, the impact is high, the design is strong, is the modern industrial and agricultural products, one of the indispensable new alternative materials.

Application:

1. Aerospace, Helicopters Model Drone, UAV, FPV, RC Model Parts

2. Manufacture Fixtures And Tooling, Industrial Automation

3. Sports Equipment, Musical Instruments, Medical Device

4. Building Construction Repair And Strengthening

5. Car Interior Decoration Parts, Art Products

| Product Name |

Carbon Fiber Pole |

| Material |

100% Carbon Fiber |

| Color |

Black or custom |

| Surface |

Matt/Glossy |

| Size |

Custom thickness and length |

| Fiber Specifications |

1K/3K/12K |

| Weaving Style |

Plain/Twill |

| Fiber Type |

1.Carbon fiber+carbon fiber

2.Carbon fiber+ glass fiber

3.Carbon fiber+aramid fiber |

| Application |

1. Aerospace, RC model parts Helicopters Model

2. Manufacture fixtures and tooling

3. Industrial automation and robotics

4. Sports equipment

5. Musical instruments

6. Scientific apparatus

7. Medical device

8. Others |

| Our Product |

Carbon fiber tube, carbon fiber plate, carbon fiber profiles. |

What is a 3K Twill Carbon Fiber Tube?

Carbon fibers are known for their high tensile strength (stretch/pull). The threads are very small and are normally bundled together to make a stronger “rope” called a tow. A common tow in this application uses 3000 fibers (called 3K). Even though a tow may contain 3000 carbon fibers it is still small. These tows are woven together in a crisscross pattern to form a very thin fabric sheet.

The term “Twill” refers to the pattern of the weave which is more complex than a simple 1x1 weave pattern. Common twill weaves may include 2x1, 2x2, and 3x1 patterns. These patterns have proven to be stronger than 1x1 weaves.

The manufacturer will use a lightweight clear epoxy to impregnate the weave to hold the carbon fiber in place as it is formed into a round tube. The epoxy adds some strength to the tube, but its main job is to spread the load evenly over all the fibers for maximum durability. Lastly, a very thin spray coat is applied to produce a gloss or matte finish.

(Many “cheap” carbon fiber tubes found online will use material other than carbon, such as fiberglass fibers. Some produce tubes with paper that have a twill pattern on it.)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!