Product Description

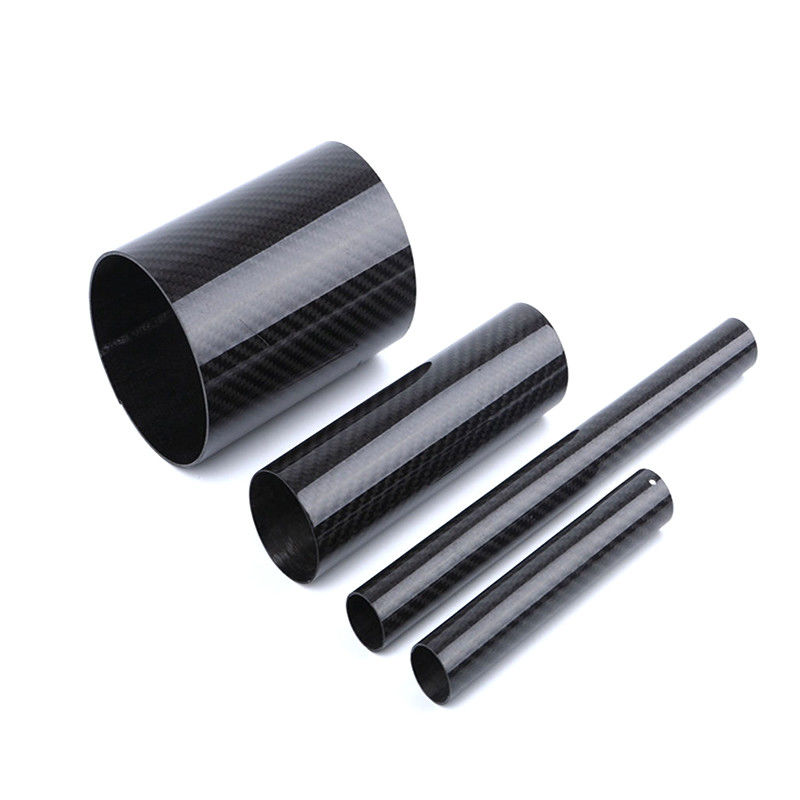

Advanced Material Experts - 3K Large Diameter Carbon Fiber Tube

Large Diameter Carbon Fiber Tube Description:

Our Carbon Fiber tubes are designed for the best strength to weight ratio. We use a full wrap of 3K filament fabric impregnated with strong clear epoxy, then a fine gloss or matte finish is added. There are no fillers! These CF tubes provide a perfect balance between strength, stiffness, and weight. This design creates a very light tube, strong enough for Multi-copter design and their numerous crashes. Also, the twill design prevents damage from twisting the tube, enabling these tubes to handle heavier loads. These tubes are very different from the common "kite" tubes.

Other advantages include handling the pressure of motor blocks, preventing rotation failure, and crushing of the arm material common in multi-copter drone builds.

Lightweight, large-diameter carbon fiber tube comprised of bi-directional, woven carbon fiber. This tubing is designed for large applications, such as telescope projects or lightweight drums. Our carbon fiber large tubes come with a textured finish on both the inside and outside for easy bonding and painting.

Main Performance:

* Light weight,1.5 g/cm³

* Super strength

* High modulus

* Corrosion-resistant

* Never rust

* UV-resistant

* Durable

* Radiation-resistant

* X-ray transparency

* High temperature-resistant

* Supremely high rigidity

* Eco-friendly

* Great dimensional stability

Features:

1. Made of high modulus 100% carbon fiber with epoxy resin.

2. Great replacement for the low-grade aluminum wing tubes.

3. Weighs only 1/5 of steel and 5 times stronger than steel.

4. Low Coefficiency Of Thermal Expansion, High-Temperature Resistance.

5. Good Tenacity, Good Toughness, Low Coefficiency Of Thermal Expansion.

Application:

1. Aerospace, Helicopters Model Drone, UAV, FPV, RC Model Parts

2. Manufacture Fixtures And Tooling, Industrial Automation

3. Sports Equipment, Musical Instruments, Medical Device

4. Building Construction Repair And Strengthening

5. Car Interior Decoration Parts, Art Products

| Product Name |

Large Diameter Carbon Fiber Tube |

| Material |

100% Carbon Fiber |

| Color |

Black or custom |

| Surface |

Matt/Glossy |

| Size |

Custom thickness and length |

| Fiber Specifications |

1K/3K/12K |

| Weaving Style |

Plain/Twill |

| Fiber Type |

1.Carbon fiber+carbon fiber

2.Carbon fiber+ glass fiber

3.Carbon fiber+aramid fiber |

| Application |

1. Aerospace, RC model parts Helicopters Model

2. Manufacture fixtures and tooling

3. Industrial automation and robotics

4. Sports equipment

5. Musical instruments

6. Scientific apparatus

7. Medical device

8. Others |

| Our Product |

Carbon fiber tube, carbon fiber plate, carbon fiber profiles. |

What is a 3K Twill Carbon Fiber Tube?

Carbon fibers are known for their high tensile strength (stretch/pull). The threads are very small and are normally bundled together to make a stronger “rope” called a tow. A common tow in this application uses 3000 fibers (called 3K). Even though a tow may contain 3000 carbon fibers it is still small. These tows are woven together in a crisscross pattern to form a very thin fabric sheet.

The term “Twill” refers to the pattern of the weave which is more complex than a simple 1x1 weave pattern. Common twill weaves may include 2x1, 2x2, and 3x1 patterns. These patterns have proven to be stronger than 1x1 weaves.

The manufacturer will use a lightweight clear epoxy to impregnate the weave to hold the carbon fiber in place as it is formed into a round tube. The epoxy adds some strength to the tube, but its main job is to spread the load evenly over all the fibers for maximum durability. Lastly, a very thin spray coat is applied to produce a gloss or matte finish.

(Many “cheap” carbon fiber tubes found online will use material other than carbon, such as fiberglass fibers. Some produce tubes with paper that have a twill pattern on it.)

LIJIN's carbon fiber tubes have been used in high-end drone assemblies, marine and aircraft applications. We are proud to offer simple high-quality products at a discounted price.

These small and large diameter carbon fiber tubes offer great versatility, both in material selection and layup schedule. Typical reinforcement materials include carbon fiber, fiberglass, and aramid fibers. In addition, core materials can be added between the high-strength skins, creating a sandwich structure. Many of the materials available for flat plate sandwich cores can also be used when producing sandwich core walls for custom tubes, with the most common examples being honeycomb and thermoformable form. Each custom carbon fiber tube construction method has specific advantages: pure laminate composite tubes result in thin walls that retain the mechanical, thermal, and electrical properties of the fiber, while sandwich core walls provide a lightweight means to increase local wall stiffness.

Given the wide variety of choices available for small and large diameter carbon fiber tubes, the selection of materials and layup schedule often come from the project requirements. A good example telescopes, where the low thermal expansion of solid or sandwich core carbon fiber tubes provides substantial improvements over metal tubes, thus offering the astronomer more reliability with temperature change. Another example is the fabrication of radomes, which often use solid fiberglass or foam-filled fiberglass sandwich construction. A third example is in the creation of high-quality drums, where the material and layup direction can be optimized for both resonances and acoustic damping. One final example is pressure vessels, which require thicker walls with adequate resistance to the high hoop stresses present in these applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!