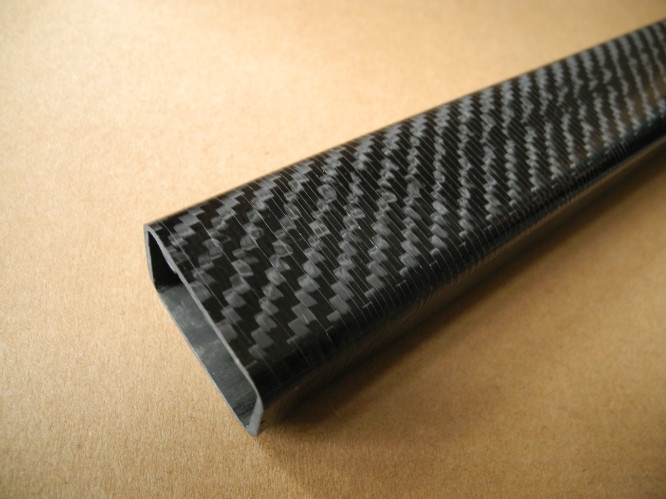

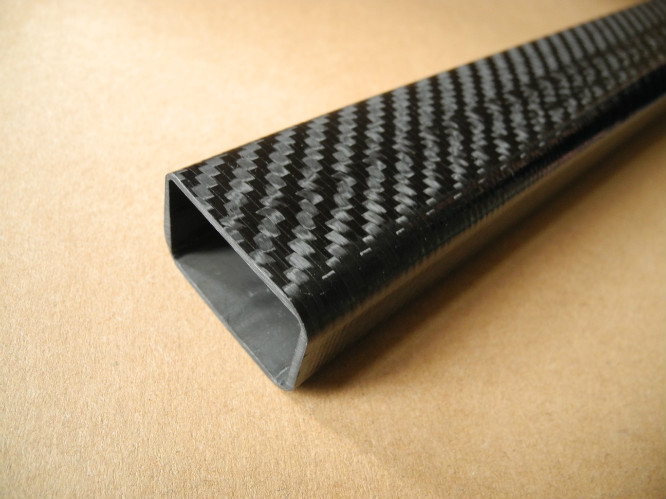

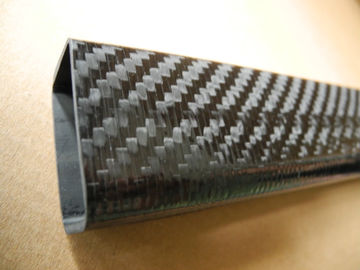

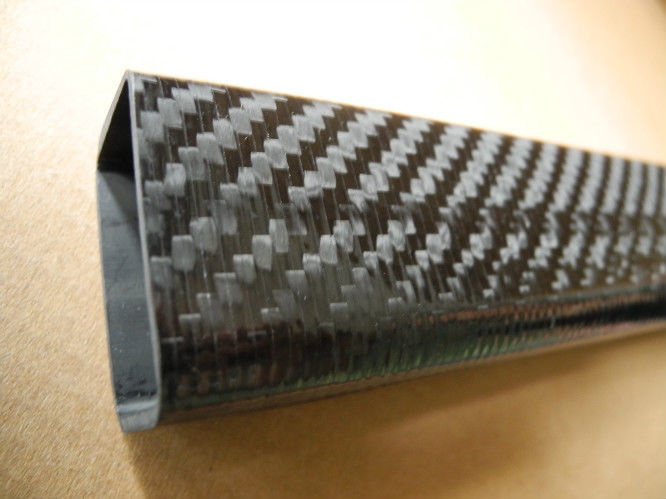

Product Description

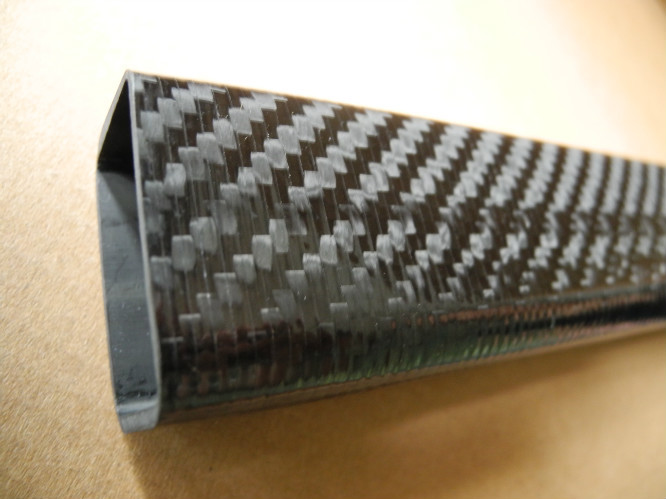

Moulded vacuum All kinds of Carbon Fiber Products Profile tube circular tube.

Performance

|

• Superior Dimensional Stability

|

|

• Wide Temperature Range Use

|

|

• Consistent Cross Section

|

|

• Lasting Performance

|

|

• Excellent Structural Properties

|

|

• Environmentally Safe

|

Material: all the tubes, 3 k, 12 k, twill, plain appearance

Thickness: can set according to customer's request

Weight: according to customer's requirement

Surface: grinding, extinction, highlights, mirror

Main use: general

Main material: carbon fiber, glass fiber and aramid fiber fabrics presoak.

Merit: light weight, high strength, high temperature resistant, long service life, beautiful appearance, etc.

Case note: the above products can be formulated according to customer's requirements

Carbon fiber is a kind of elegant appearance, excellent mechanical properties of new materials.He's less

than a quarter of the steel, lighter than aluminium, 20 times than the strength is iron.Compared with

titanium, steel, aluminum and other metal materials, carbon fibre on the physical properties of high

strength, high modulus, low density, low thermal expansion coefficient, etc, can be called the king of

new materials.Therefore, can be used in the automobile and motorcycle accessories, sporting goods,

construction, hardware accessories, leather textile, aircraft manufacturing, military field, wind power

blades and other industrial fields.Due to the use of carbon fiber products can greatly reduce the weight

of the materials, which can significantly improve the efficiency of function.According to the report, the

quality of the shuttle per 1 kg less, can relieve the carrier rocket 500 kg.Carbon fiber in addition to the

general characteristics of carbon materials, high temperature resistant, friction resistance, conductivity,

thermal conductivity and corrosion resistance, etc., its appearance has obvious anisotropy, soft, can be

processed into a variety of fabrics, and because of its small density, along the fiber axis show a very high

strength, carbon fiber reinforced epoxy resin composite material, its than strength, modulus of composite

indicator, is among the highest in the existing structure material.Carbon fiber has excellent denier is

almost no other materials like carbon fibre has so many series of excellent performance, so in the purport,

stiffness, heavy, fatigue properties, high temperature resistance, chemical stability and so on have strict

requirements of domain, carbon fiber composite materials have an irreplaceable revenge.

Carbon fiber products with "material is qualitative light, high modulus, high strength" etc, and will gradually

replace the traditional steel, glass fiber reinforced plastic and other materials.My company production of

carbon fiber sheet, carbon fiber tubes, carbon fiber, carbon fiber car parts, carbon fiber motorcycle

accessories and other products, at home and abroad has been widely used in aerospace, sports

equipment, medical equipment, civil construction and reinforcement reinforcement engineering,

automobile and motorcycle industry, metal jewelry, and other fields.

Has many excellent properties of carbon fiber products, carbon fiber axial strength and high modulus,

low density, high performance than, no creep, not resistant to ultra high temperature oxidation

environment, good fatigue resistance, heat and electrical conductivity between non-metal and metal,

small thermal expansion coefficient and anisotropy, good corrosion resistance, permeability good X-ray.

Good conductive heat conduction performance, good electromagnetic shielding, etc.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!