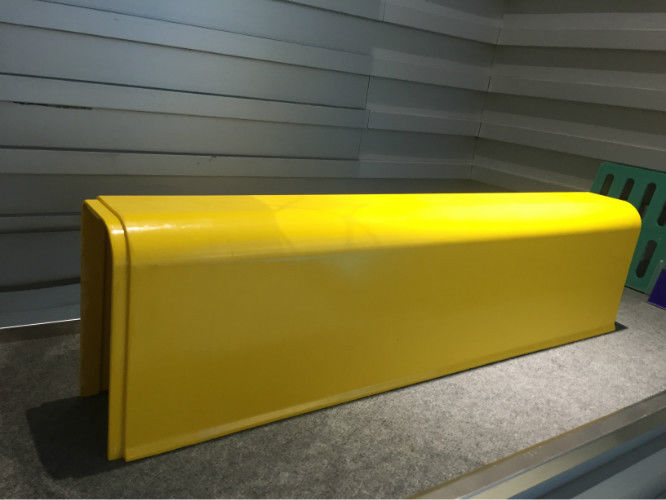

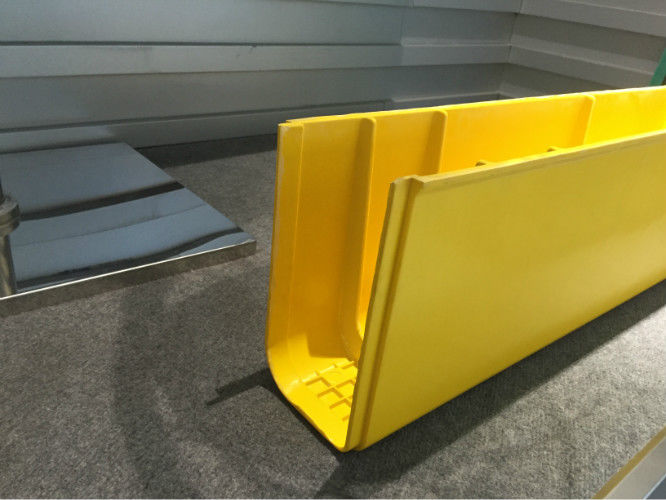

Product Description

Used in municipal engineering of Fiberglass Profiles Curbstone Yellow.

Description

The abbreviation of SMC is English Sheet Molding Compound, Chinese name is called the Sheet Molding

Compound.SMC is a kind of semi-dry method of manufacturing glass fiber reinforced thermosetting

products moulded the middle material, composed of unsaturated polyester resin, low shrinkage/low profile

additives, initiator, release agent, such as mineral filler in advance mix into a paste, then add thickening

agent, colorant, such as after mixing, to fully impregnated, chopped glass fiber thickening process, finally

forms the sheet "Sandwich layer" type structure.

Such products for glass fiber products carbon fiber profile, used in municipal engineering, automobile,

aerospace engineering, chemical plants, etc

The abbreviation of BMC is English Bulk Molding Compound, group that Chinese mold plastic.BMC is a

kind of semi-dry method of manufacturing glass fiber reinforced thermosetting products moulded the

middle material, composed of unsaturated polyester resin, low shrinkage/low profile additives, initiator,

release agent, such as mineral filler in advance mix into a paste, then add thickening agent, colorant, etc.,

with different length of glass fibers, in special material kettle stirring, thickening process, eventually

forming clumps of intermediate materials.

Main Performance

|

* (Fiberglass 1.95,aluminum 2.7 and steel 7.85) less than 1/5 of steel.

|

|

* Super strength. About 5 times of steel.

|

|

* Corrosion-resistant. Anti-acid,anti-alkali.

|

|

* Never rust. Which is more excellent than stainless steel.

|

SMC/BMC molding process

SMC/BMC moulding process is to put a certain amount of mould plastic metal in the mould, under certain

temperature and pressure effect, make the mould plastics within the mold heat plasticizing, pressure flow

and full of cavity shaping curing and one way to get products.

The characteristics of the SMC/BMC moulding products

1. High mechanical strength

2. Light weight material

3. Strong corrosion resistance

4. High dielectric strength

5. Sealed performance is good

6. Flexible product design

7. Product appearance

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!