Product Description

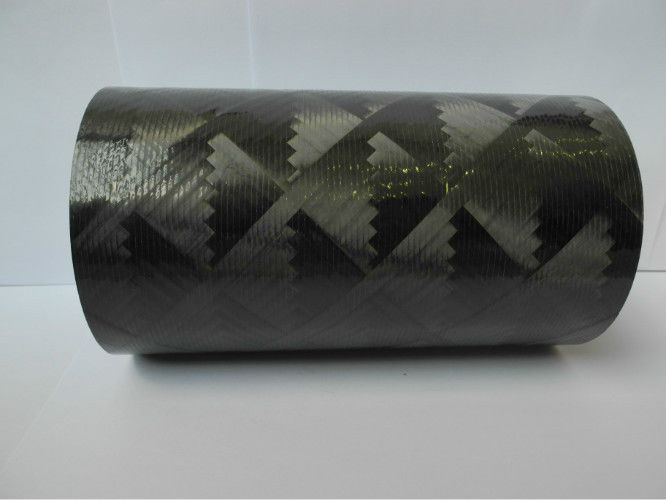

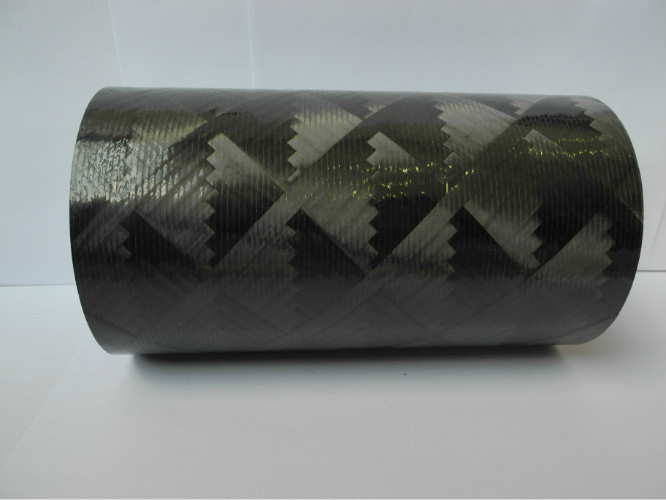

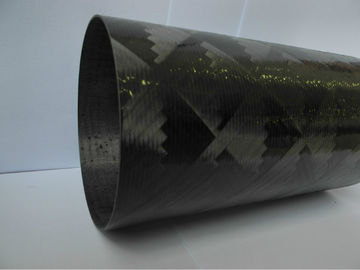

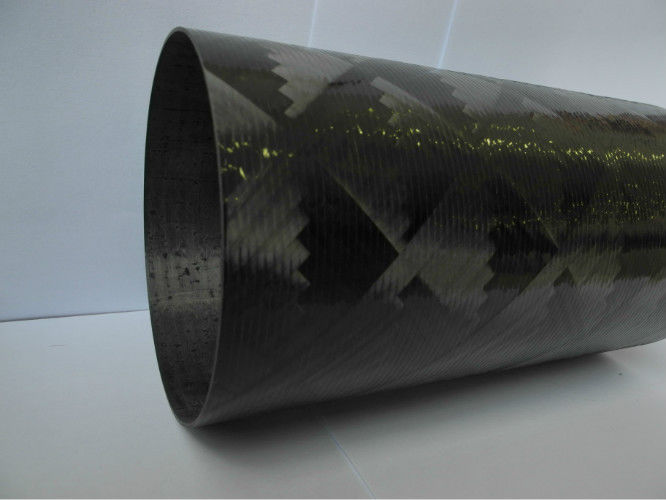

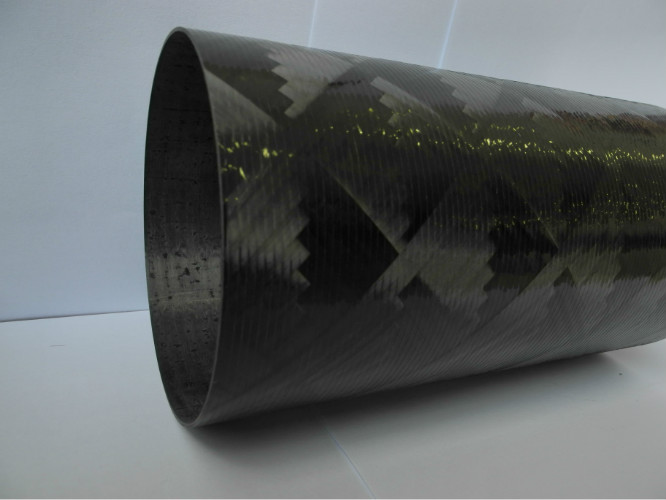

Filament wound winding High Modulus Carbon Fiber Tube Large size Full Carbon.

Introduction

Carbon fiber composite material with the advantages of high strength, high modulus, low density, carbon

fiber has become one of the high performance of the most important.Carbon fiber composite material has

been widely used in aerospace, Marine, automotive, sports equipment and other fields, its important

features are:

1. Light weight, high strength

Its specific gravity 1.4 1.8 g/cm, is only a quarter of the steel, transportation and installation is very

convenient, compared with the plastic products, its strength is plastic products of dozens of times, so

remarkable characteristics is light weight, high strength carbon fiber composite materials.

2. corrosion resistance, anti-aging, long service life

Carbon fiber products to acid, alkali, salt, some organic solvents and other corrosive erosion, in the field

of corrosion protection has the incomparable superiority to other metals, and have good water resistance

and aging resistance, so no matter in corrosive environment and bad in the open air, wet environment

operation, its service life can reach more than 15 years.

3. good security, good impact resistance, can design high,

Carbon fiber products with excellent electrical insulation, non-magnetic, no spark, and can according to

user needs to be flame retardant treatment, and allow the repeated bending without permanent

deformation, has good resistance to impact and fatigue resistance performance.It also can be designed

according to the requirements of different cross section.

Specification

|

The surface of the grain

|

3K twill

|

|

Effect of surface

|

Matte, light

|

|

Post processing

|

Drill, such as processing

|

Carbon fiber winding of molding process

Winding molding process is soaked in resin adhesive solution of continuous fiber (or cloth belt, presoak

yarn) on winding to the mandrel according to certain rules, and then after curing, demoulding, obtain

products.According to the filament winding forming physical and chemical condition when the resin is

different, divided into dry winding, wet winding and half dry winding 3 kinds.(1) dry winding Dry winding is

adopted through presoak rubber processing presoak yarn or, on a winding machine after soften to

viscous flow winding onto the mandrel.Because of presoak yarn (or with) is a professional production, to

strictly control the resin content (accurate to 2%) and presoak yarn quality.Therefore, dry winding can

accurately control the quality of the product.Dry winding process is the biggest characteristic of high

production efficiency, winding speed can reach 100 ~ 100 m/min, winding machine cleaning, labor health

condition is good, high product quality.The downside is winding equipment is expensive, need to increase

in yarn manufacturing equipment, so the investment is bigger also, dry low interlaminar shear strength

of winding products.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!