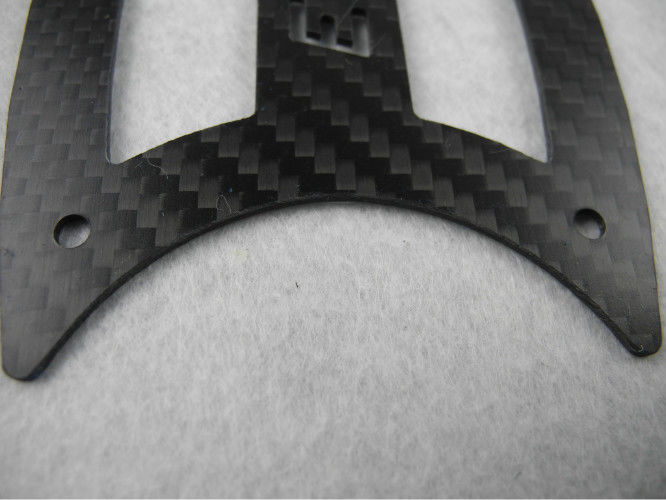

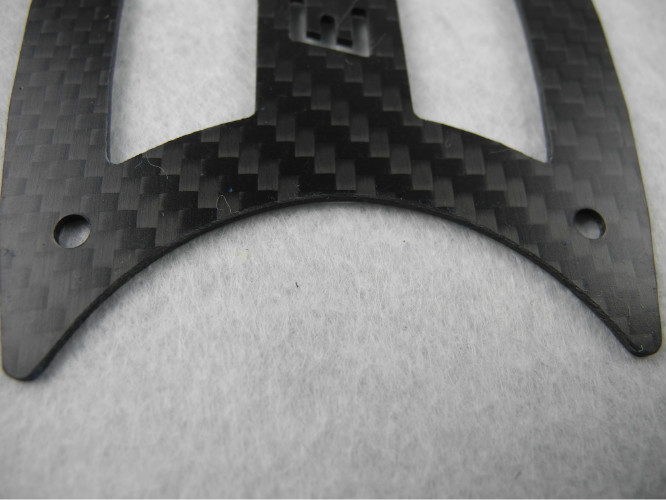

Product Description

Carbon fibre Chassis with CNC OEM service Carbon Fiber CNC Service Chassis OEM .

Materials processing

Laser processing can be used for cutting processing and machining of composite materials, can be a

very small cutting seam width and nearly parallel to the cutting seam side, its processing efficiency is high,

but the thermal damage is very large.Ultrasonic vibration cutting, can improve the cutting condition of

the carbon fiber composite material, a knife when ultrasonic vibration cutting material, adopt the small

cutting parameter can effectively reduce the main cutting force.

Current research of carbon fiber composite materials of grinding is relatively small, mainly in the

comparison of different grinding wheel grinding performance, need to promote grinding in the application

of carbon fiber composite materials.

Specification

|

Lead Time

|

Based on the quantity of order (Usually 2-3 weeks)

|

|

Terms of trade

|

EXW, FOB, CIF

|

Measures to prevent drilling outlet layered Carbon Fiber CNC technology:

under the condition of open structure, the export of hole surface with a hard high density board support

and cushion, this can effectively prevent hole export layering and fracturing.In situations where conditions

permit, make carbon fiber composite material components can be considered in exports face labeled with

1 ~ 2 layers of glass cloth, and component curing at the same time, to stay after drilling the hole will be

glass cloth torn off, it also can prevent the hole exit surface layer.In the export of carbon fiber composite

materials need to drill hole surface evenly coated with a layer of structural adhesive, after waiting for

curing drilling, Carbon Fiber CNC also can prevent the hole exit surface layering and fracturing.

Carbon composite material is short for carbon fiber reinforced carbon composite material, is also a kind

of advanced composite materials. It is made of carbon fiber and fabric, woven fabric reinforced carbon

matrix composites. The carbon/carbon composites is mainly composed of various types of carbon, carbon

fiber, resin carbon and carbon deposition. This completely by artificial design, made of pure carbon

composite material has many excellent properties, besides having high strength, high rigidity, size

stability, oxidation resistance and wear resistance and other properties, but also has higher fracture

toughness and pseudoplastic. Especially in high temperature environment, high strength, not melt

non-combustible, is only homogeneous ablation. This is not to match any metal material. Therefore

widely used in missile warhead, solid rocket motor nozzle, as well as aircraft brake disk and other

high-tech fields.

***Pictures shown below are only to display the carbon fiber CNC capability,experience and Quality from LijinCarbon.

LijnCarbon will NOT disclose or share any drawings or product detail to third parties.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!