Product Description

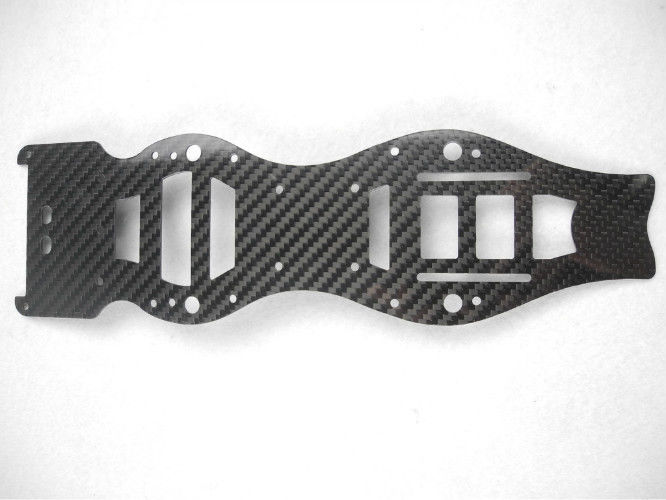

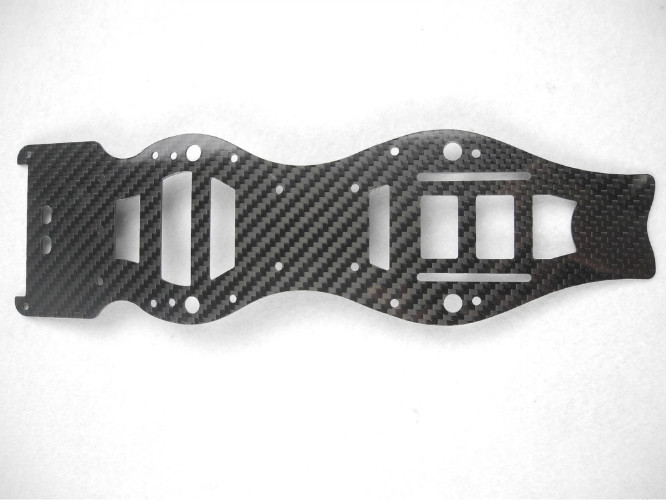

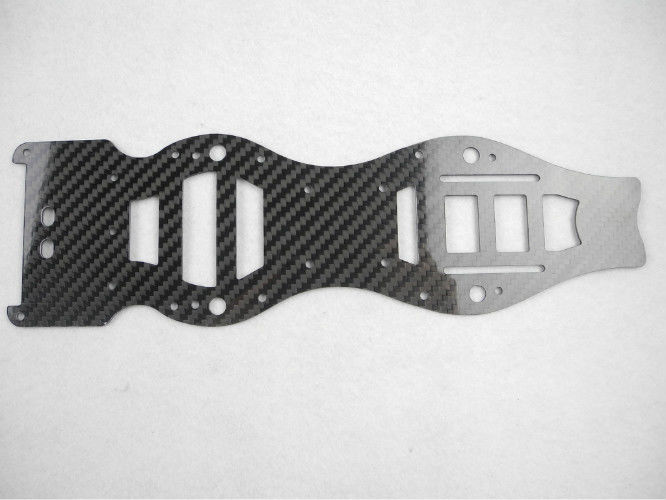

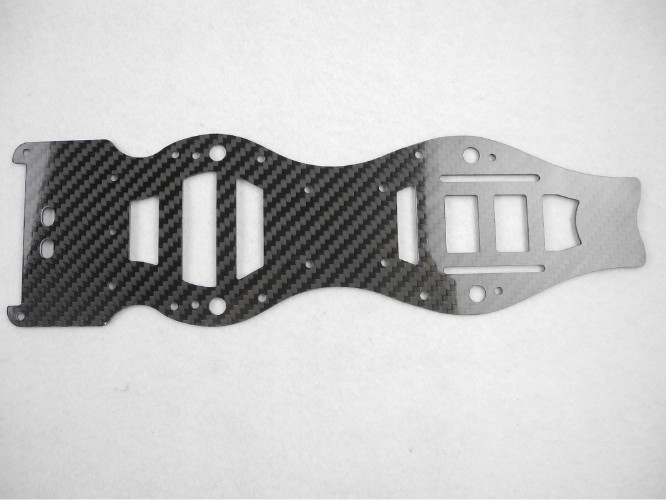

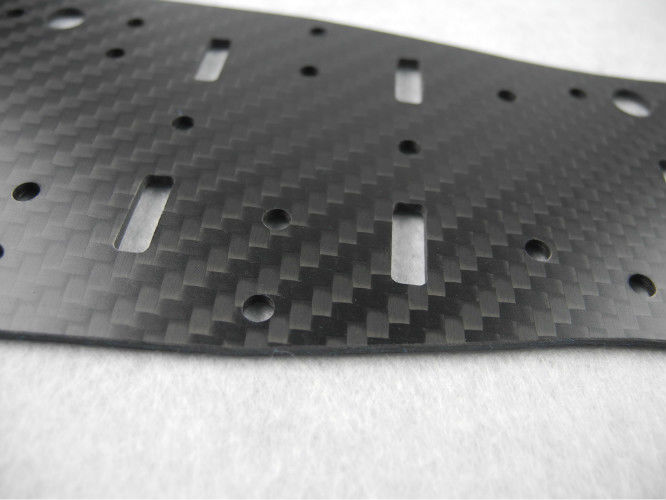

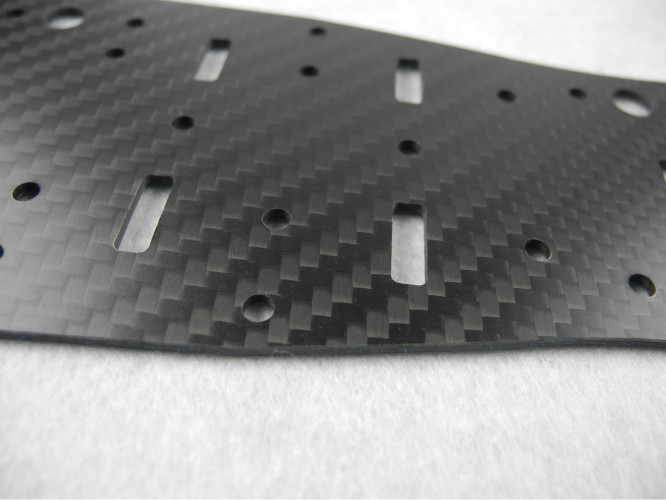

Drone Chassis Carbon Fiber CNC Service Cutting Drilling Sample Orders 3-5 Days Ship.

Other technology

Carbon fiber composite materials using silicon carbide cutting tools for cutting process, the cutting effect

is good.

The cutting process parameters and the thickness of carbon fiber composite materials have very big

concern, feeding should be inversely proportional with the thickness.

Laser processing can be used for cutting processing and machining of composite materials, can be a

very small cutting seam width and nearly parallel to the cutting seam side, its processing efficiency is

high, but the thermal damage is very large.Ultrasonic vibration cutting, can improve the cutting condition

of the carbon fiber composite material, a knife when ultrasonic vibration cutting material, adopt the

small cutting parameter can effectively reduce the main cutting force.

Because of the small cutting force, so ultrasonic vibration cutting carbon fibre composite can be used

for thin-walled parts processing.

Current research of carbon fiber composite materials of grinding is relatively small, mainly in the

comparison of different grinding wheel grinding performance, need to promote grinding in the

application of carbon fiber composite materials.

Specification

|

Sample

|

Acceptable

|

|

Quality System

|

100% Inspection before shipment

|

|

Lead Time

|

Based on the quantity of order (Usually 2-3 weeks)

|

|

Terms of trade

|

EXW, FOB, CIF

|

Product advantage: high strength, light weight, good toughness.Appearance fashion, high-grade

generous, for the appearance of the most popular decorative material.

Measures to prevent drilling outlet layered fiber technology:

under the condition of open structure, the export of hole surface with a hard high density board support

and cushion, this can effectively prevent hole export layering and fracturing.In situations where conditions

permit, make carbon fiber composite material components can be considered in exports face labeled

with 1 ~ 2 layers of glass cloth, and component curing at the same time, to stay after drilling the hole will

be glass cloth torn off, it also can prevent the hole exit surface layer.In the export of carbon fiber

composite materials need to drill hole surface evenly coated with a layer of structural adhesive, after

waiting for curing drilling, also can prevent the hole exit surface layering and fracturing.

Materials

※ The surface of carbon fiber are gel, it possesses the advantages of not easy to clean water, rain

water has the function of the automatic cleaning.

※ The advantages, more light and bright, easy cleaning, thin shell and good toughness.

***Pictures shown below are only to display the carbon fiber CNC capability,experience and Quality from LijinCarbon.

LijnCarbon will NOT disclose or share any drawings or product detail to third parties.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!