Product Description

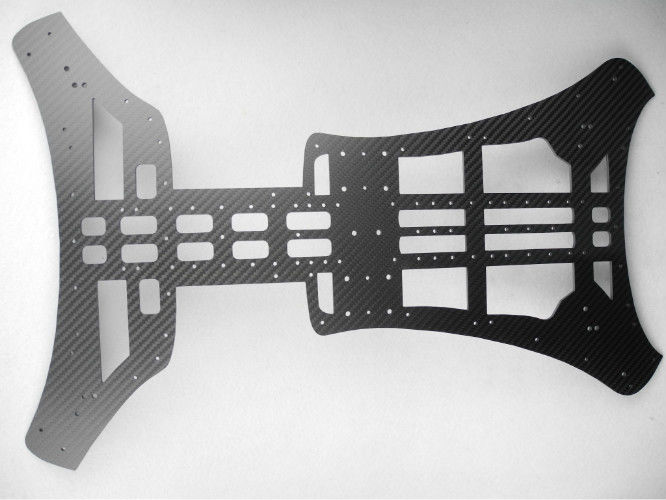

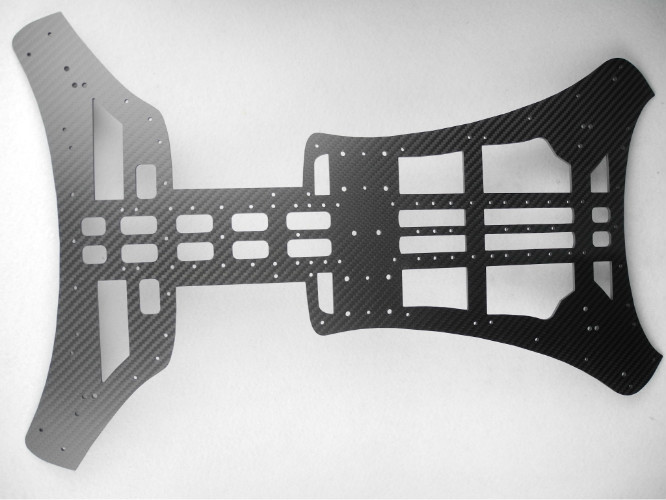

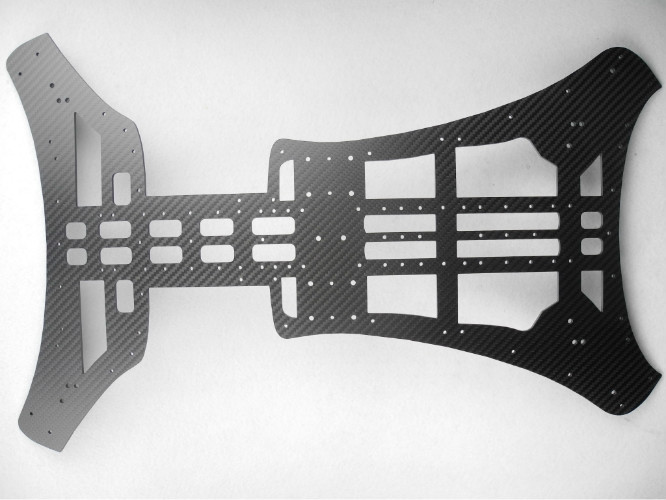

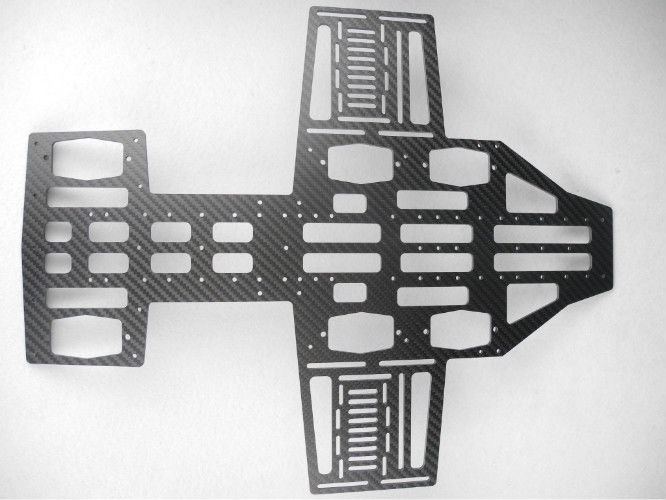

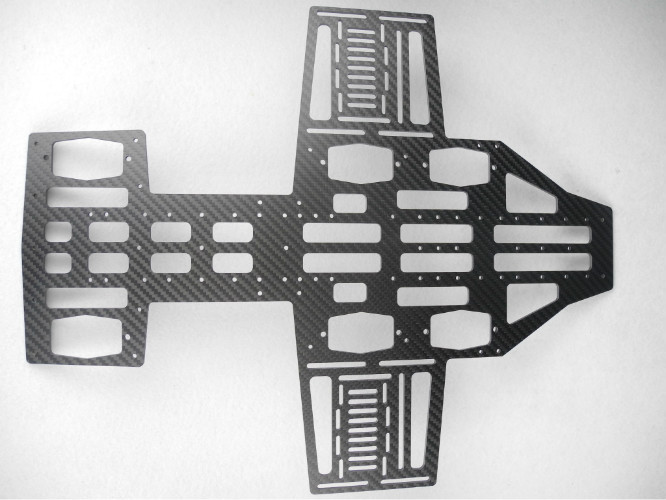

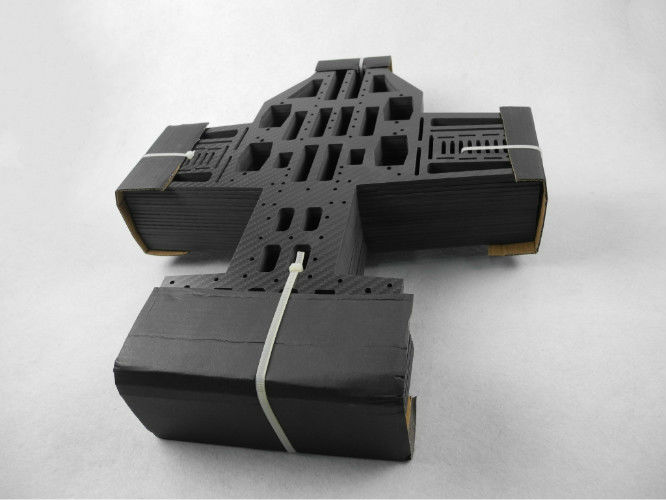

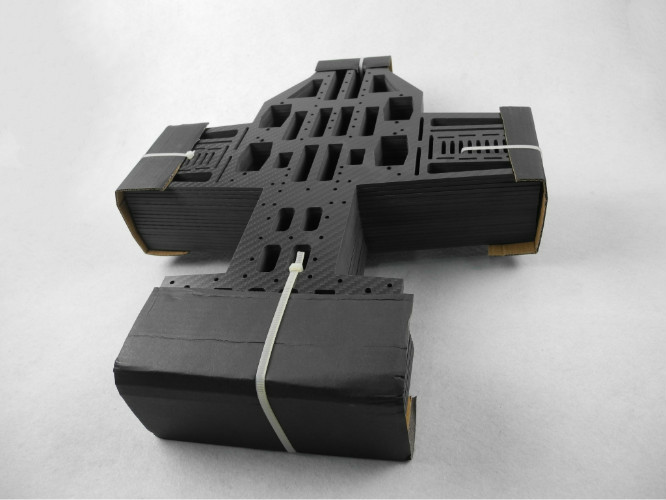

Customized Production Carbon Fibre CNC Service OEM services Duadcopter Frames.

Main processing method

(1) Carbon fiber composite material low

interlaminar strength, in the process of drilling, if the composite component of drilling axial force is too

large, lead to interlaminar stress too much, more than the matrix resin strength will cause defects such

as delamination

(2) Carbon fiber composite materials belong to anisotropic materials, the direction of fiber

layer has a larger effect on system holes, especially when one-way slab system hole, the hole of the

stress concentration is bigger, easy to cause defects such as splitting.

(3) Carbon fiber composite material hardness, when drilling bit wear quickly.

(4) Carbon fiber composite material thermal conductivity is poor, in the process of drilling bit and

composite materials to produce large amounts of friction heat and carbon fiber composite material

thermal conductivity is small, the heat is difficult to eliminate the cutting area in processing

temperature rising rapidly, causing bit annealing, accelerating bit wear.

(5) Carbon fiber composite materials have shrinkage phenomenon, this is due to the small thermal

conductivity of carbon fiber composites, and the linear expansion coefficient and elastic recovery were

larger.

Specification

|

Material

|

CARBON FIBER, aluminum, stainless steel, carbon steel, brass, copper, titanium

and so on.

|

|

Machining Equipments

|

Machining Center,CNC Engraving Milling Machine,CNC Lathe Machine,

Lathe Machine,Milling Machine,Punching Machine ,CNC milling machines,

Centerless grinding, and many other precision equipments

|

FAQ

1. Q: Can I order the next samples first?

A: Can we welcome to order samples for testing and check the quality of the mixed sample

is acceptable.

2. Q: How long is delivery time?

A:The sample takes 1-3 days, mass production needs 10 to 15 days, is ultimately based on orders,

offline will negotiate with you.

CNC processing

(1) Second, motors, the accuracy of mechanical products is higher and

higher, the CNC machining center fixture accuracy requirement also more and more high

(2) Three is efficient,

highly efficient fixture can reduce processing time, improve labor productivity, reduce labor intensity

(3) Four is flexible, adaptable flexibility is similar to that of a machine tool, through the adjustment and

combination way, improve the adaptability to process variables, better meet the modern machinery

industry the needs of the many varieties, small batch production.

***Pictures shown below are only to display the carbon fiber CNC capability,experience and Quality from LijinCarbon.

LijnCarbon will NOT disclose or share any drawings or product detail to third parties.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!