Product Description

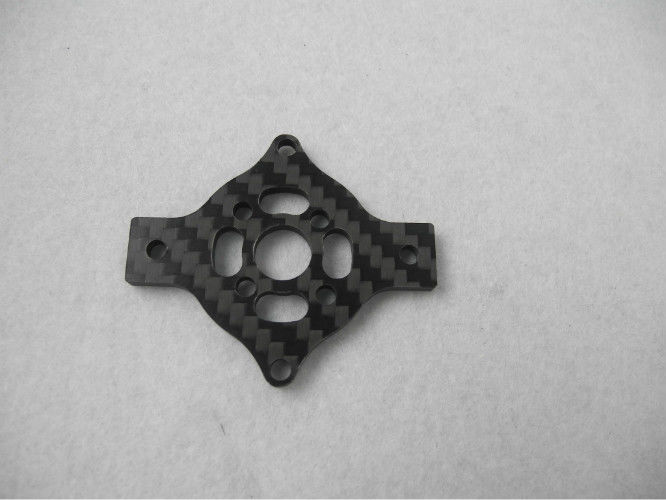

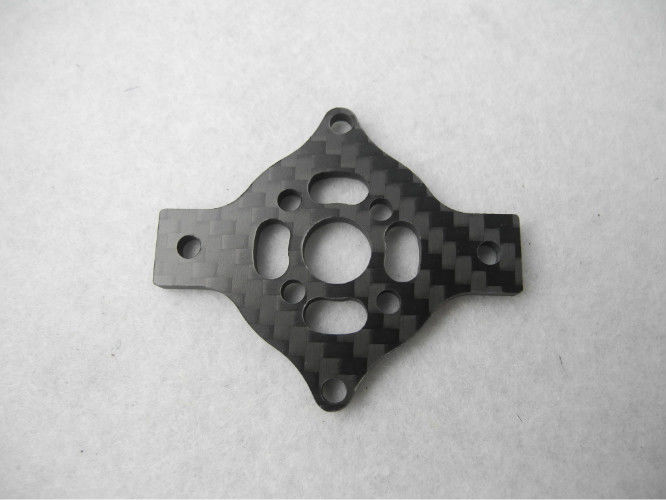

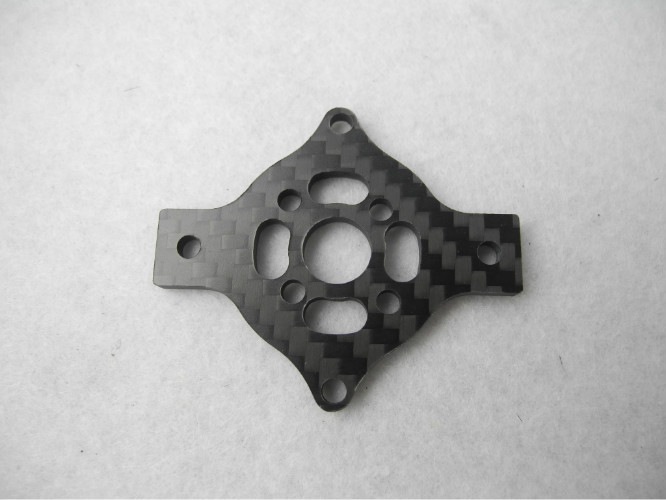

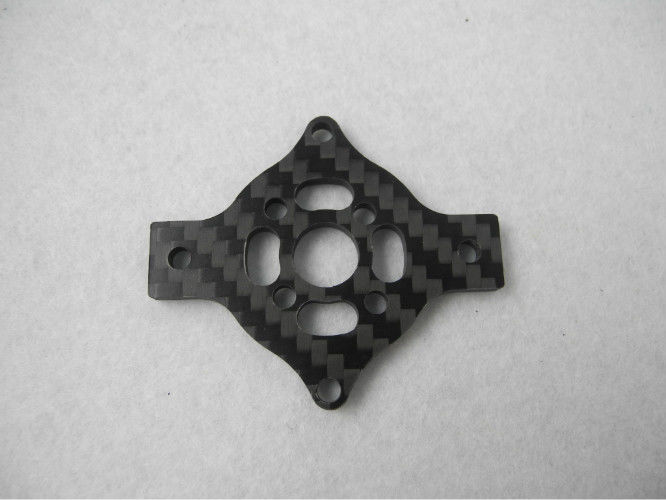

Cnc machining Carbon Fiber CNC Service for Motor Mount OEM CNC.

Processing characteristics

Carbon fiber composites made from composite laminated commonly use,There are usually two kinds

of composite form,Is a kind of carbon fiber in the base Gone are arranged in the body,The direction of

the fibers in each layer,Often refer to this kind of composite materials for unidirectional fiber composite

materials;Is a kind of layer fiber direction is different point of view, often referred to as multidirectional

fiber composite materials.

Specification

|

Material

|

carbon fiber cnc service

|

|

Size Of Plate

|

400X500(mm)

|

|

Layup

|

Standard(0°&90°)

|

|

Tolerance

|

±0.10mm

|

Carbon fiber advantage nc machining characteristics

► Environmentally Safe

► Variety Of Colors For Choice

► Non-Magnetic Electromagnetic

► Consistent Cross Section

► Dimensional Stability

► Non-Conductive Thermally And Electrically

► Wide Temperature Range Use

►Superior Dimensional Stability

►Smooth finish on surface

Advantages and disadvantages

Carbon fiber enhanced composite material has a few good features in advanced materials and systems.

Two common application of carbon fiber is the weight of the strength and hardness under the satisfying

requirements, including space, military structure, robot, wind power, production equipment, sports

equipment and other many aspects.When combined with other materials to achieve high toughness,

specific application may also be applied to the conductivity of carbon fiber and the high thermal

conductivity.Finally, in addition to the basic mechanical properties of carbon fiber has a unique and

beautiful surface finish.

Although carbon fiber with unmatched by other materials properties, but also some aspects need to be

weighed.First solid carbon fiber is not easy to deformation, when under the condition of mild bending will

not deformation, on the contrary once more than the limit carbon fiber will complete to break the bad.In the

design process engineer must understand the features, especially in the design of the safety factors to

consider.At the same time it is worth noting that the carbon fiber composite material is more expensive

than traditional.Using carbon fiber in the production of high quality building materials (such as solid carbon

plate, plate, pipe) requires higher levels and many intricate process, construction from the assembly,

highly optimized parts and components require very high technology level and the special tools and

equipment.

***Pictures shown below are only to display the carbon fiber CNC capability,experience and Quality from LijinCarbon.

LijnCarbon will NOT disclose or share any drawings or product detail to third parties.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!