Product Description

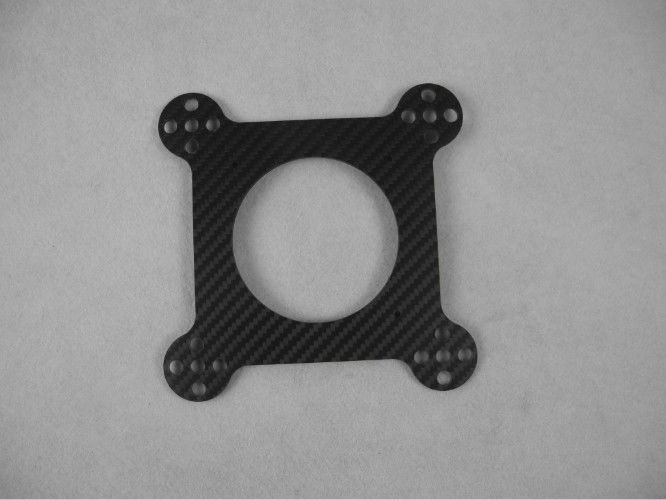

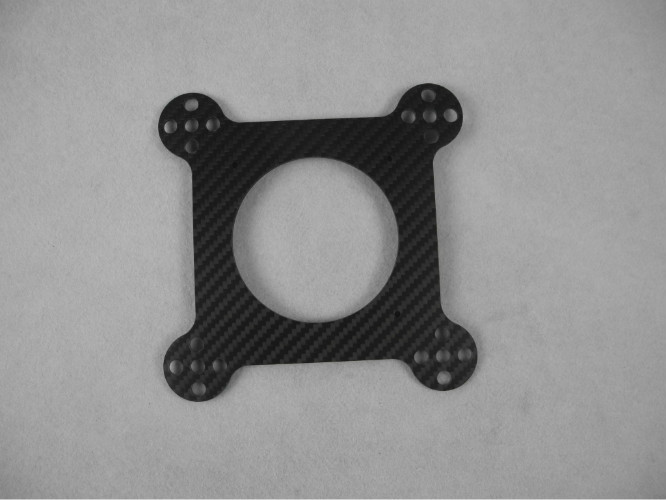

Machining service--Carbon Fiber CNC Service OEM Chassis with Countersink Holes.

Introduction

Carbon fiber VS metal

When design combination can't simple comparison of carbon fiber, copper, aluminum, or plastic properties,

because the material is the same (same characteristics of all points), has the same properties

(the characteristics of each axis is the same)., by contrast, the strength of carbon fiber on the axis

directionof it, on the direction of the characteristics of carbon fiber and maximum impact mechanical

properties of the base.Carbon fiber parts is comprehensive is neither uniform nor the direction.

The performance of carbon fiber and steel at the same time its weight and similar plastic close, so the

strength of the carbon fiber is lighter than (weight ratio) and the hardness is much higher than steel and

plastic.Construction and application of concrete depends on the details of the components, such as a foam

core layer has the very high bending strength than the weight, but not necessarily compression or extrusion

their structure is the only, so we can't use in your application of carbon fiber to replace the same

thickness of the steel.To determine the specific requirements of security and comfort of the products is the responsibility of the customer, this is through engineering analysis and experimental verification.

Specification

|

Guide

|

The displacement speed

|

Positioning accuracy

|

Tolerance

|

|

Japan

|

20m/min

|

0.02mm/300mm

|

±0.1mm

|

Carbon fiber advantage nc machining characteristics

UV Resistant Inhibited

Environmentally Safe

Variety Of Colors For Choice

Non-Magnetic Electromagnetic

Consistent Cross Section

Dimensional Stability

The comparison of strength, hardness and other materials

Carbon fiber is very strong, this is typical of the strength of the engineering material weight ratio and

stiffness to weight ratio, particularly in the increased weight can lead to a life cycle cost or not satisfied

with the performance of structure design.Hardness of a material is measure by its elasticity coefficient,

the coefficient of carbon fiber typical values 20 msi (138 Gpa), and its maximum tensile strength values

are typical 500 ksi (3.5 Gpa).High strength and hardness of carbon fiber material also has a higher

application value and can be through the professional heat treatment process.Compared with the

2024 - T3 aluminum coefficient of typical values only 10 msi and the maximum tensile strength only 500

ksi typical values, and the coefficient of 4130 steel typical values is 30 msi and the maximum tensile

strength values are typical 125 ksi.

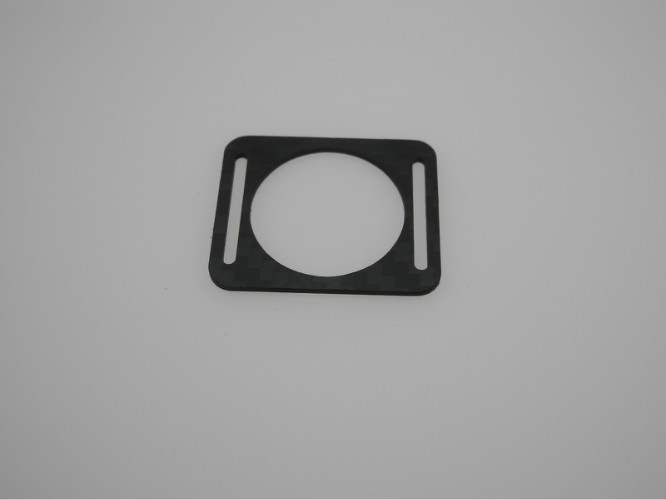

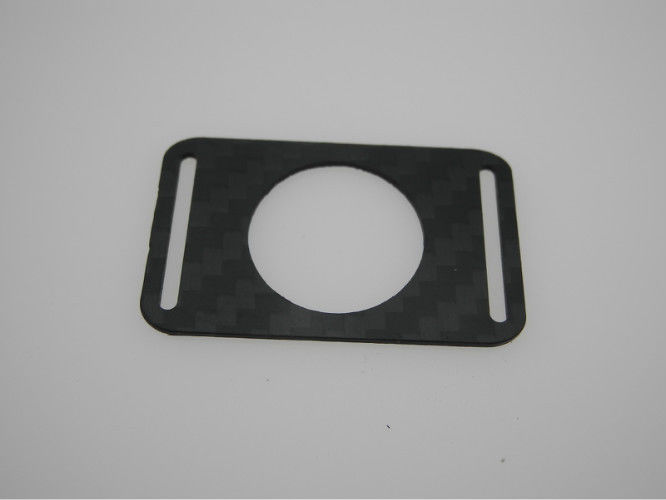

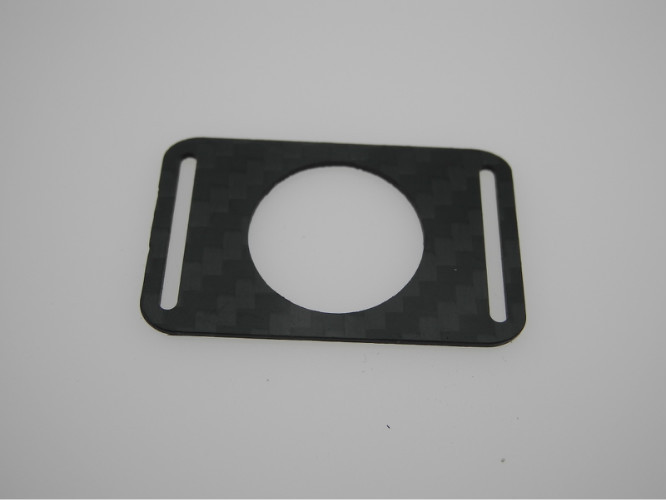

***Pictures shown below are only to display the carbon fiber CNC capability,experience and Quality from LijinCarbon.

LijnCarbon will NOT disclose or share any drawings or product detail to third parties.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!