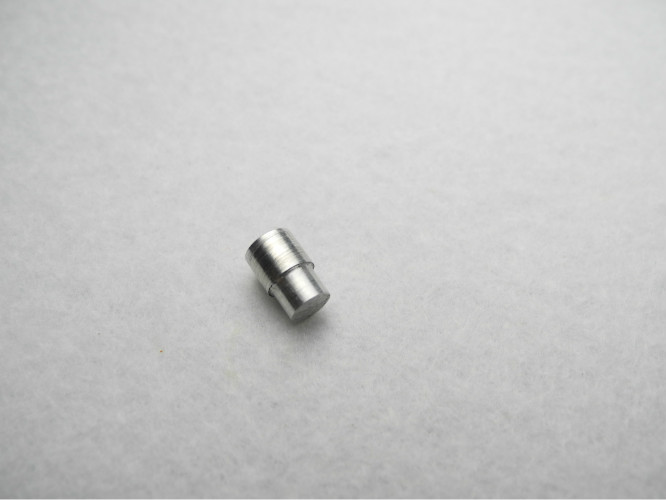

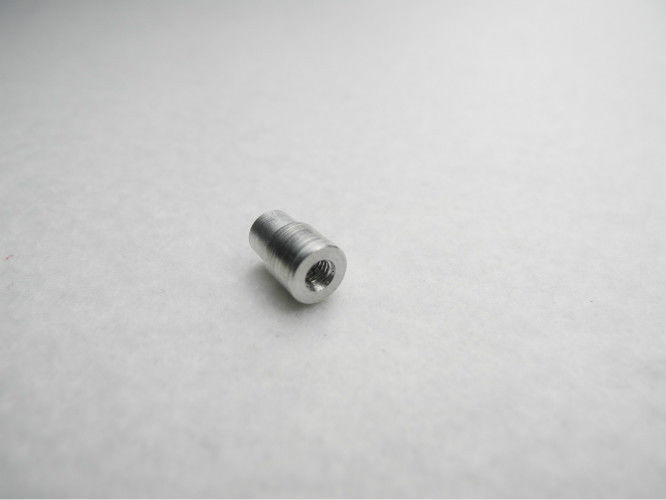

Product Description

Custom processing Aluminum Clamps CNC Silverwhite anodizing Sample Orders Acceptable.

Introduction

1. Metal Fabrication:Lathe,Turning,Milling,Engraving,Grinding,Stamping,Lasering,Boring,Broaching,

Drilling,Rolling,Punching,Aluminum Extrusion.etc

2. Surface Treatment:Plated nickel,coppe,zinc.etc.Hard Anodizing,powder coated, polished,sand blasted,

chemical surface treatment, or according your requirement.

3. Advanced Equipment:CNC Machining Center;CNC Lathe;CNC Milling Machine;Precision Cutting Machin

Description

|

Cooperative partners

|

Intel, Sodick, TPK, FDK, Xiamen Airline, Hollyland, etc.

|

|

Packaging

|

PP bags, carton, wooden cases, or on requirement

|

|

Lead time

|

3-4 workdays for samples,7-15 workdays for mass production.

|

Advantage

► Offering free and quick prototyping ( normally 1 week)

► A series of secondary service available, like casting; forging; welding; heat treatment etc

► Offering consultancy service on components machining

A look into CNC machines used for aluminium

Aluminium CNC machines have to be operated a bit differently to CNC Machines used for other metals as

Aluminium is a very soft metal and ha some properties that makes cutting, drilling and tapping difficult in

them.

Aluminium CNC Machines have to be programmed correctly to ensure that there is less wear and tear of

the cutting blades, drills and the machine and to ensure that the finish of the product is as per the

requirements.

This requires a lot of knowledge and experience about Aluminium CNC machines and how aluminium

behaves and our has a team of experts who have the required knowledge to ensure that all the

requirements are met.

The use of aluminum enginnering in metal worls is very important as it helps them to keep in touch with

the latest technologies that are being introduced in the world of aluminium products manufacturing.

Our company that upgrades the machinery in their factory regularly and any new technology is immediately

analyzed by the aluminium engineering team and introduced into the factory if it is something that will help

with the manufacturing process.

Our has a high reputation amongst its customers and that is due to the high quality standards that they

are able to maintain over the years and the prompt delivery, which is considered to be very important.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!