Product Description

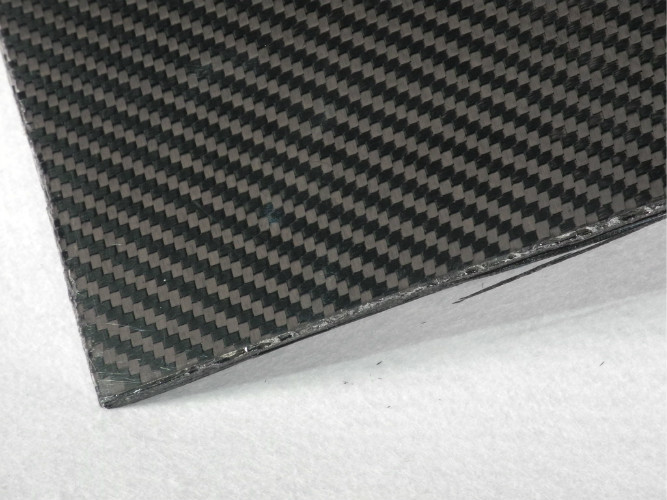

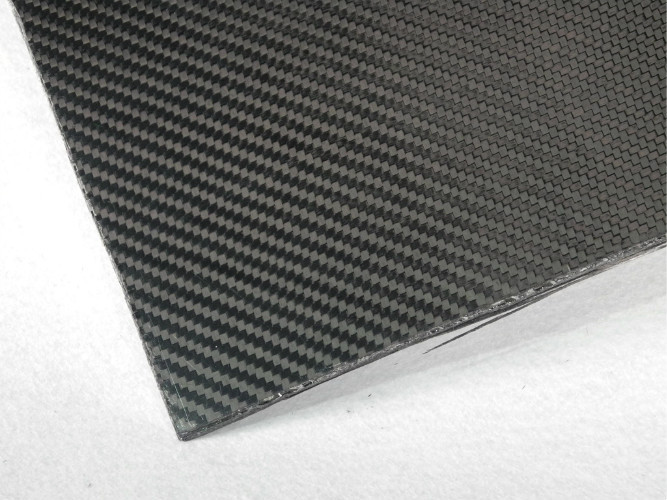

Full Carbon Fiber Plate 340MM × 410MM Thickness 1.5mm Twill Standard Layup CF plate .

Compared with the carbon fiber cloth, carbon fiber board has the following

advantages

1. construction is convenient, easy to guarantee construction quality,

2. carbon fiber plate than carbon fiber cloth is easy to keep straight, more conducive to carbon fiber.

3. a 1.2 mm thick plate is equivalent to 10 layers of carbon fiber cloth

Performance

** Light weight – Less Density – 20% of Steel

** High strength and Perfect Surface

** High UV and Corrosion Resistance

** Superior and Precision Dimensional Stability

** Consistent Cross Section

** Excellent Structural Properties and Lasting Performance

Specification

|

Length

|

340mm

|

|

Width

|

410mm

|

|

Thickness

|

1.5mm

|

|

High quality

|

100% pure carbon fiber/full/plate (not including glass fiber)

|

|

Weaving/pattern direction

|

twill

|

|

The two sides

|

Matte

|

The development

carbon fiber plate is a move to expand, including building a manufacturing plant in California,

turned out unfortunately. The investment didn't generate the anticipated returns, leading to a

decision to pull out of the area. Courtaulds ceased carbon fiber production in 1991, though ironically

the one surviving UK carbon-fiber manufacturer continued to thrive making fiber based on Courtaulds's

precursor. Inverness-based RK Carbon Fibres Ltd has focused on producing carbon fiber for industrial

applications, and thus does not need to compete at the quality levels reached by overseas producers.

Each carbon filament thread is a bundle of many thousand carbon filaments. A single such filament is a

thin tube with a diameter of 5-8 micrometers and consists almost exclusively of carbon. The earliest

generation of carbon fibers (i.e., T300, and AS4) had diameters of 7-8 micrometers. Later fibers

(i.e., IM6) have diameters that are approximately 5 micrometers.Precursors for carbon fibers are

rayon, polyacrylonitrile (PAN) and pitch. Carbon fiber filament yarns are used in several manufacturing

techniques: the direct uses are for prepregging, pultrusion, filament winding, weaving, braiding, etc.

Carbon fiber yarn is rated by the linear density (weight per unit length, i.e. 1 g/1000 m = 1 tex) or by

number of fibers per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon

fiber is three times as strong as 1,000 carbon fibers, but is also three times as heavy. This count is

usually expressed as 3K, 12K, 6K, etc. This thread can then be used to weave a carbon fiber filament

fabric or cloth. The appearance of this fabric generally depends on the linear density of the yarn and

the weave chosen. Some commonly used types of weave are plain, 2x2 twill, 4x4 twill and satin.

Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!