Product Description

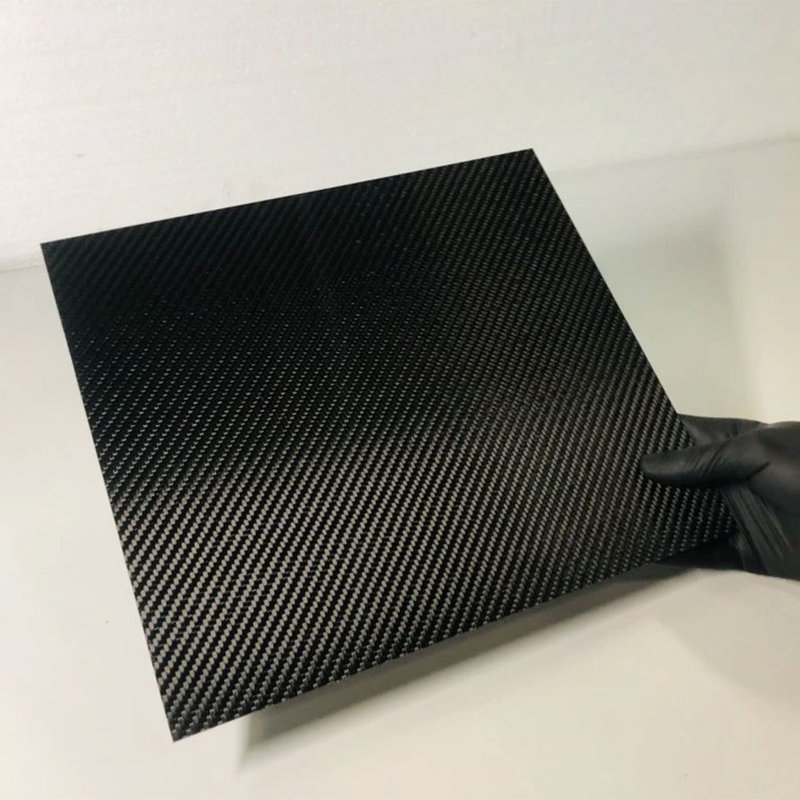

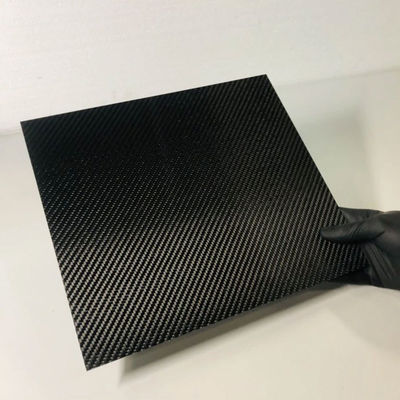

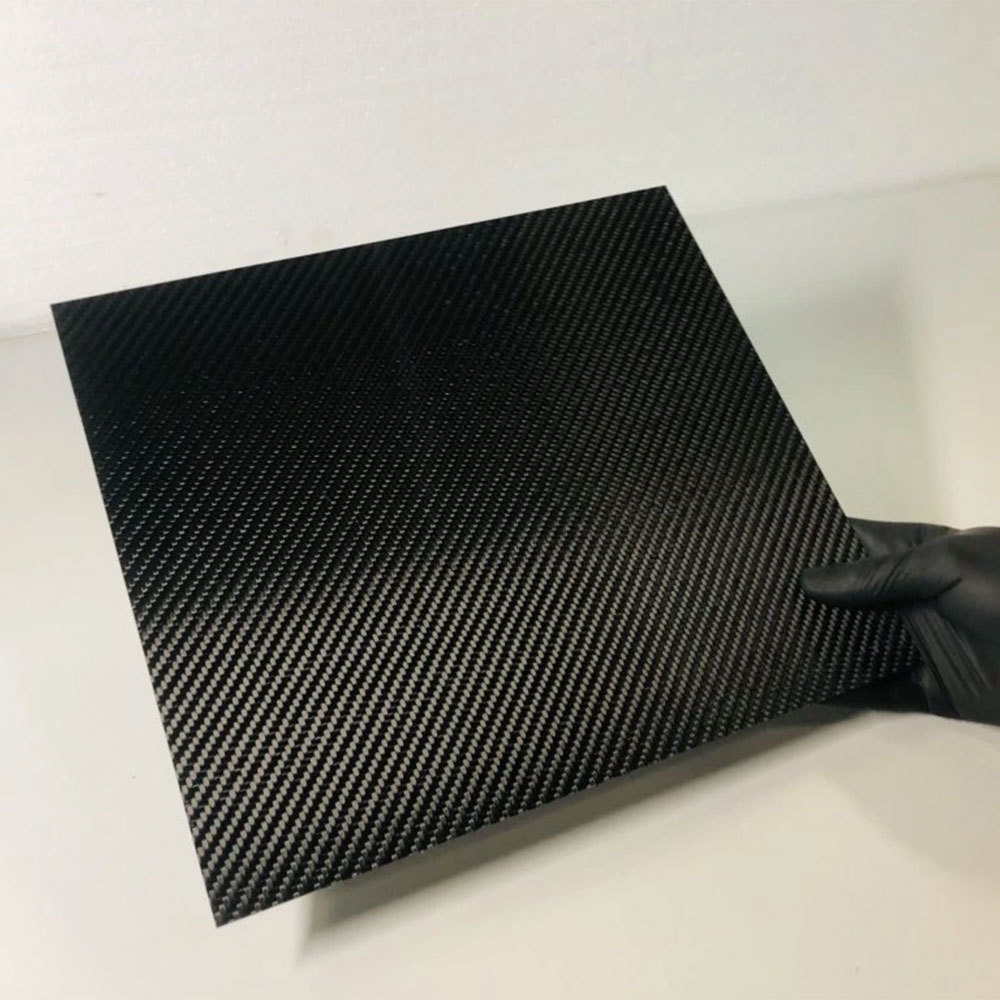

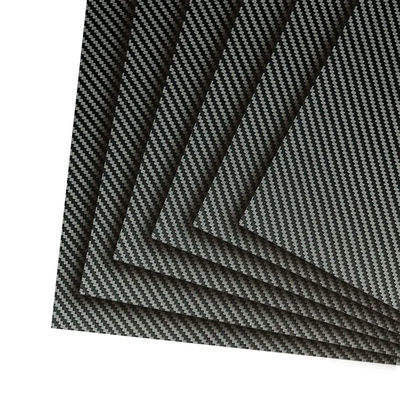

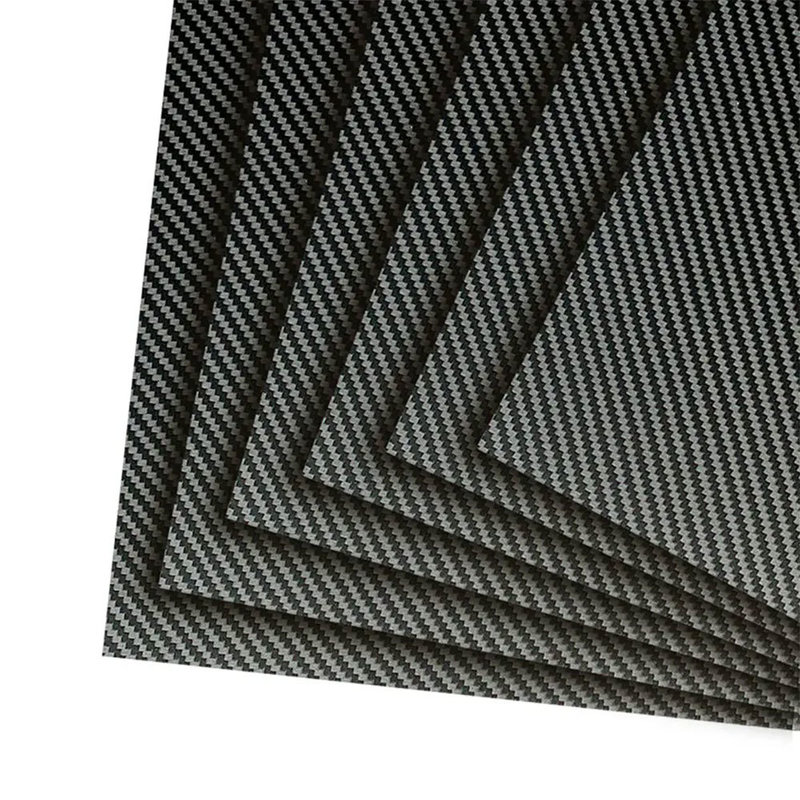

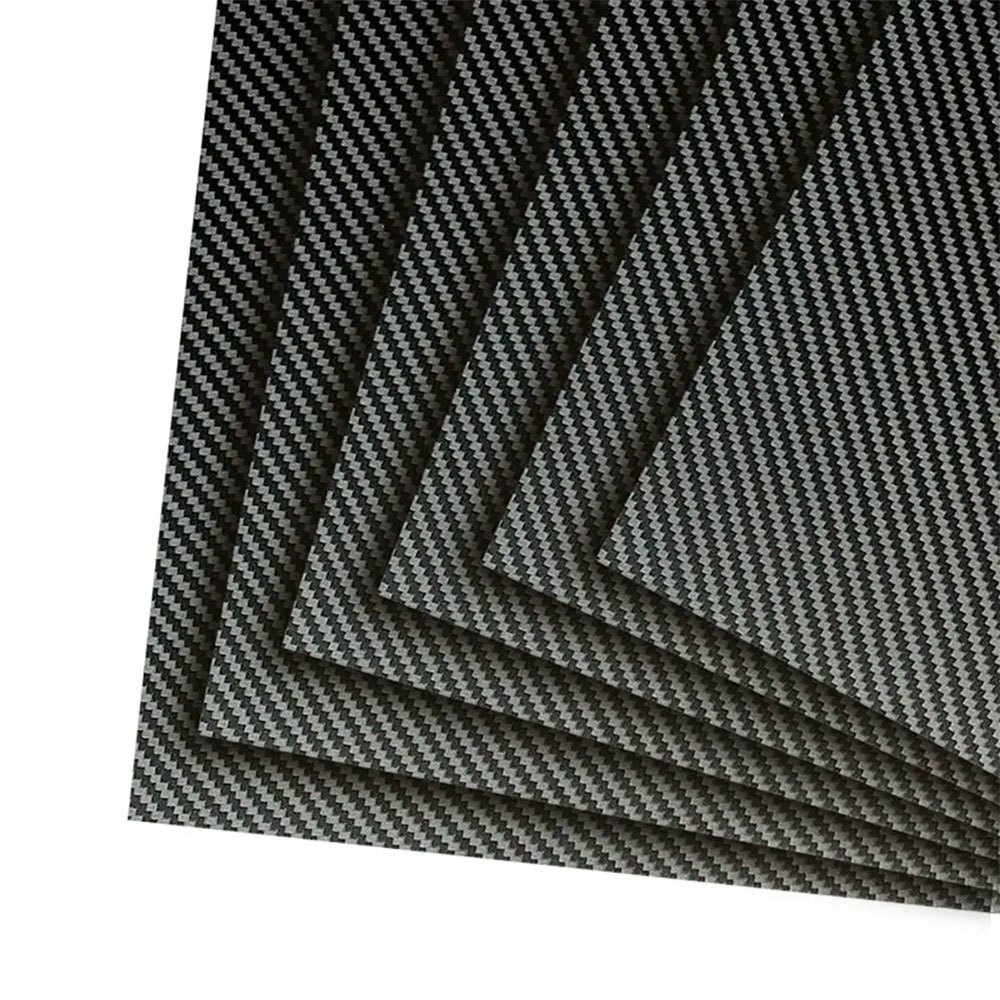

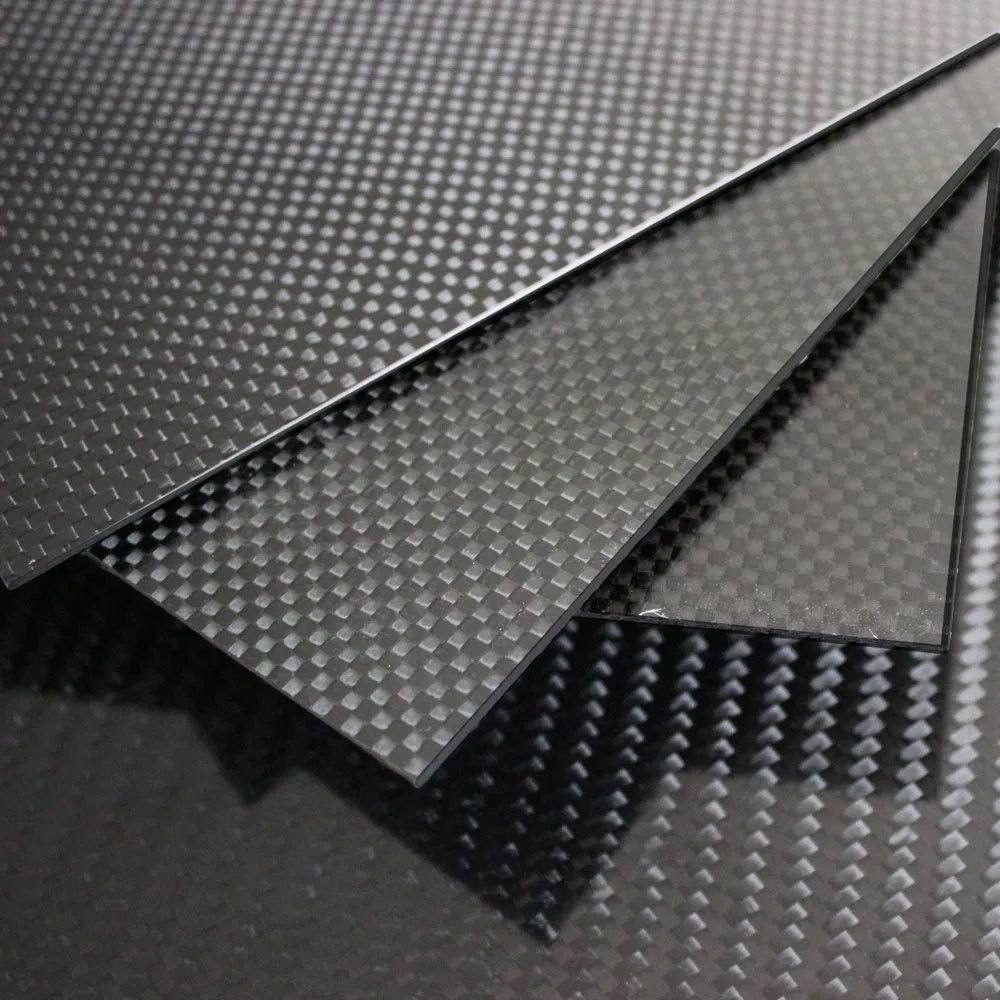

Durability 100% 3K Carbon Fiber Parts Manufacturing Prepreg Carbon Fiber Plate

Prepreg Carbon Fiber Plate is a high-performance composite material made from pre-impregnated carbon fiber fabrics that are pre-coated with an epoxy resin system. These plates are cured under high temperature and pressure, ensuring precise fiber-resin ratios and superior mechanical properties.

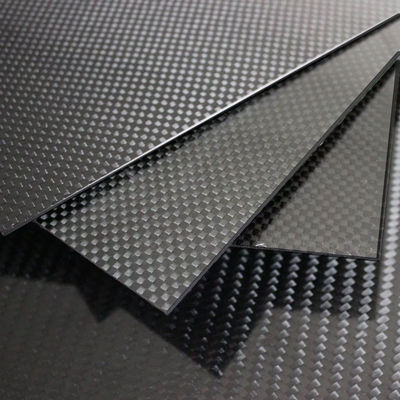

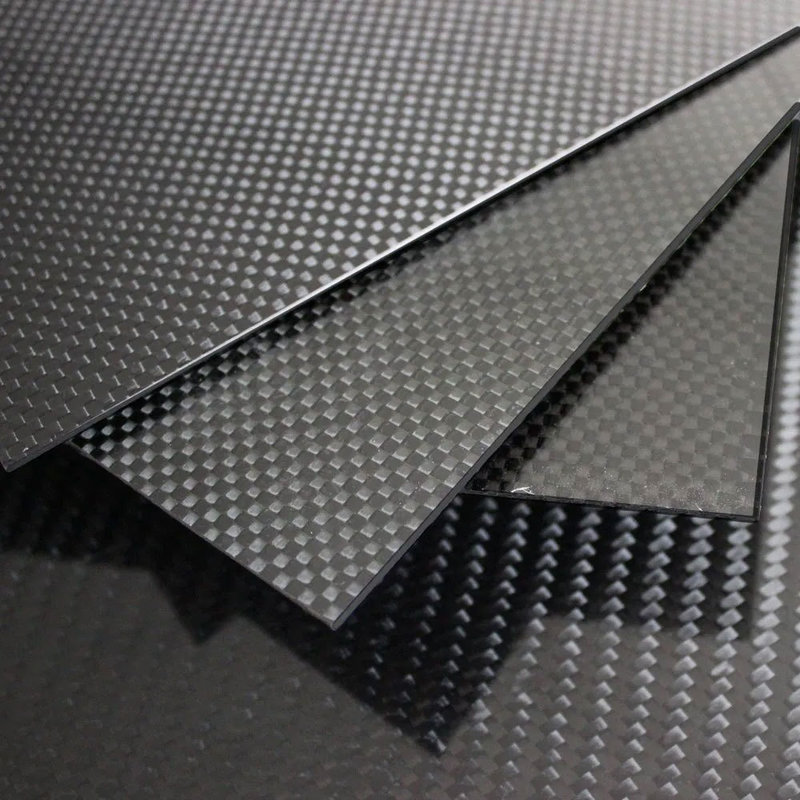

Prepreg carbon fiber plates offer exceptional strength-to-weight ratio, stiffness, and dimensional stability, making them ideal for demanding applications. They also feature a smooth surface finish and uniform structure, which enhances both aesthetics and performance.

Features

- Made from premium pre-impregnated carbon fiber fabrics

- High strength, stiffness, and lightweight

- Excellent dimensional accuracy and stability

- Smooth, glossy, or matte surface finish options

- Superior fatigue resistance and impact performance

- Consistent fiber-to-resin ratio for reliable quality

Our professional capabilities:

1, Prepreg / Autoclave

Pre-preg is the “top class” fabric, which, during the manufacturing process, undergoes impregnation with resin mixed with hardener. The resin protects against damage and imparts the required viscosity to ensure fabric adherence to the mold surface.

Pre-preg type carbon fiber has applications in Formula 1 racing cars, as well as in the manufacture of carbon fiber elements of sports bicycles.

When is it used? For the manufacture of premium quality products of complex design that have low weight and outstanding appearance.

Our autoclave generates a working pressure of 8 bar, which provides optimal strength of manufactured products as well as a perfect appearance of composites without any trapped air defects. After manufacturing, components undergo varnishing in the paint spray booth.

2, Resin Infusion

Resin infusion is a process whereby fabric in moulds is sealed with film/butyl tape and filled with a liquid resin. When the resin solidifies, the solid resin matrix binds the assembly of materials into a unified rigid composite.

This technique has applications in the manufacture of carbon sheets and other large items that have a moderately complex shape.

3, Manual Laminating

Manufacture of high-quality carbon fiber products requires costly technology. Dexcraft is one of the few companies that manufactures products using proprietary technologies of manual laminating that ensure high-quality composites.

Our products, manufactured using manual laminating technology, present no defects related to air bubbles in the carbon fiber visual layer. Thanks to in-mold coating technology, all manufactured elements are resistant to UV as soon as they are removed from the mold (eliminating further spraying).

4, Customized Techniques

To meet clients’ requirements and needs, we developed proprietary solutions that enable the manufacture of unique products. For many years, we built our reputation as a supplier who provides solutions where others failed.

We also offer expertise in microsphere and bladder inflation.

Carbon Fiber Sheet Plate Specification:

|

Item Name

|

Thickness

|

Length & Width

|

Weave

|

Finish

|

SKU Code

|

N.W.

|

Regular MOQ

|

1st Order MOQ

|

Ship From

|

|

05005060, Full CF Plate, Plain Weave,6K, Matte, TT

|

5

|

500mm*600mm

|

Twill

|

Glossy

|

TG05005060PLTFCF3KTT

|

2.48

|

5

|

1

|

China factory

|

|

04005060, Full CF Plate, Plain Weave,5K, Matte, TT

|

4

|

500mm*600mm

|

Twill

|

Glossy

|

TG04005060PLTFCF3KTT

|

1.94

|

5

|

1

|

China factory

|

|

03005060, Full CF Plate, Plain Weave,4K, Matte, TT

|

3

|

500mm*600mm

|

Twill

|

Glossy

|

TG03005060PLTFCF3KTT

|

1.46

|

5

|

1

|

China factory

|

|

02505060, Full CF Plate, Plain Weave,3K, Matte, TT

|

2.5

|

500mm*600mm

|

Twill

|

Glossy

|

TG02505060PLTFCF3KTT

|

0

|

5

|

1

|

China factory

|

|

02005060, Full CF Plate, Plain Weave,3K, Matte, TT

|

2

|

500mm*600mm

|

Twill

|

Glossy

|

TG02005060PLTFCF3KTT

|

0.96

|

5

|

1

|

China factory

|

|

01505060, Full CF Plate, Plain Weave,3K, Matte, TT

|

1.5

|

500mm*600mm

|

Twill

|

Glossy

|

TG01505060PLTFCF3KTT

|

0.73

|

5

|

1

|

China factory

|

|

01005060, Full CF Plate, Plain Weave,3K, Matte, TT

|

1

|

500mm*600mm

|

Twill

|

Glossy

|

TG01005060PLTFCF3KTT

|

0.53

|

5

|

1

|

China factory

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!